BCRyan

Senior Member

- Joined

- Jul 10, 2020

- Messages

- 104

- Location

- Canada

- Vessel Name

- MISTRESS

- Vessel Make

- Horizon 76 Skylounge

Hi all - I'm getting stumped by an issue that has recently cropped up and hoping someone might have some experience in this area.

My 2001 Horizon MY has Naiad stabilizers, model 254, likely original from the boat's build. During a recent trip from San Francisco to Newport, Oregon, the high temp light started coming on, so we turned the system off (thankfully it wasn't needed at that point). In Newport, I found that the sea strainer was at least half full of seaweed, and figured I had it solved as I emptied that and put everything back together.

Unfortunately, the overheating issue continues -- about 45 minutes after running the system either in "Centered" or "On", the high temp light comes on, even when the system is not working hard at all. Also concerning is that the seawater flow from the outlet (just above waterline) seems to be pretty low. I'm not 100%, but it seems like it used to be much more.

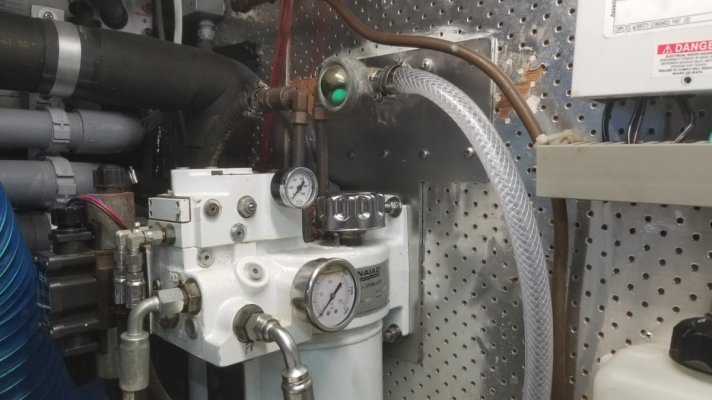

The pump (pic below) looks to be fairly new.

I've done the following to troubleshoot:

1) Bypass the Naiad heat exchanger, i.e. thru-hull -> sea strainer -> pump -> inlet hose connected directly to the outlet hose -> outlet. The flow is roaring and *significantly* greater than normal in this mode.

2) Connect the outlet of the heat exchanger to a garden hose and back-flush the HE into a bucket. Flow seems to be pretty strong and no debris came out, but this is also under tap water pressure (~60 psi??)

3) Open up the impeller chamber on the pump (everything perfectly clean).

4) Double-check the sea strainer (still clean)

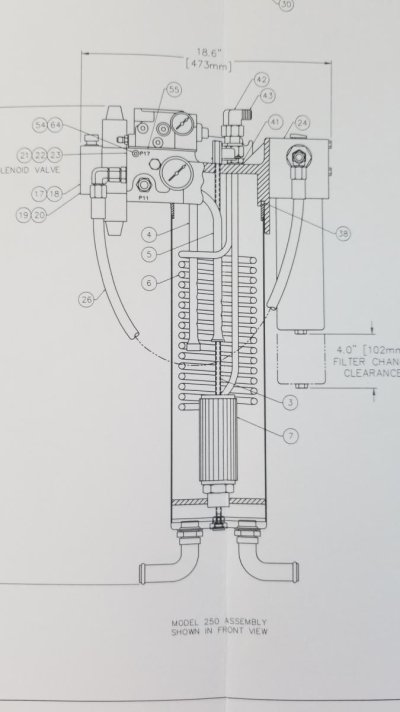

Since the flow with everything connected normally is so much less than case 1) above, I'm inclined to suspect that something in the HE piping is restricting flow. If this needs to be cleaned, does anyone know how this gets accomplished? I have the manual but it shows nothing more than a system diagram and definitely nothing about cleaning of the HE.

Some pics below. If anyone has any suggestions, I'm all ears.

Thank you!

My 2001 Horizon MY has Naiad stabilizers, model 254, likely original from the boat's build. During a recent trip from San Francisco to Newport, Oregon, the high temp light started coming on, so we turned the system off (thankfully it wasn't needed at that point). In Newport, I found that the sea strainer was at least half full of seaweed, and figured I had it solved as I emptied that and put everything back together.

Unfortunately, the overheating issue continues -- about 45 minutes after running the system either in "Centered" or "On", the high temp light comes on, even when the system is not working hard at all. Also concerning is that the seawater flow from the outlet (just above waterline) seems to be pretty low. I'm not 100%, but it seems like it used to be much more.

The pump (pic below) looks to be fairly new.

I've done the following to troubleshoot:

1) Bypass the Naiad heat exchanger, i.e. thru-hull -> sea strainer -> pump -> inlet hose connected directly to the outlet hose -> outlet. The flow is roaring and *significantly* greater than normal in this mode.

2) Connect the outlet of the heat exchanger to a garden hose and back-flush the HE into a bucket. Flow seems to be pretty strong and no debris came out, but this is also under tap water pressure (~60 psi??)

3) Open up the impeller chamber on the pump (everything perfectly clean).

4) Double-check the sea strainer (still clean)

Since the flow with everything connected normally is so much less than case 1) above, I'm inclined to suspect that something in the HE piping is restricting flow. If this needs to be cleaned, does anyone know how this gets accomplished? I have the manual but it shows nothing more than a system diagram and definitely nothing about cleaning of the HE.

Some pics below. If anyone has any suggestions, I'm all ears.

Thank you!