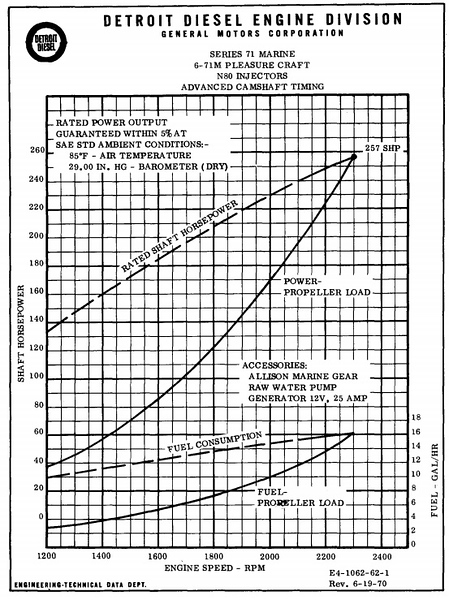

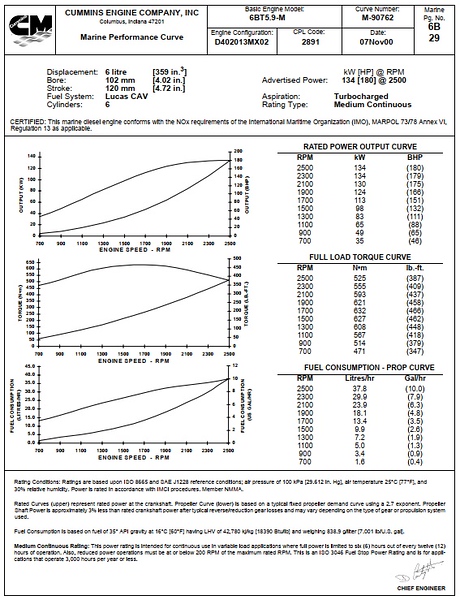

I am cost conscious . Boats with Detroits seem to be less expensive. Can Detroits be run at low rpm to save fuel? Can I take a 671TI and remove the T and the I and put in smaller injectors and get a fuel efficient engine similar to a Perkins or Lehman? Does the two cycle need to run at higher rpm to generate enough heat to run properly and get good life? In short, can I make a Detroit get fuel economy and good life somewhat similar to a 4 stroke like a Cummins, Lehman, Perkins, Yanmar? Is the two stroke Detroit by its nature not able to compete fully in the fuel economy war? I am willing to live with slower speeds as long as the hull can handle all conditions similarly to when it had higher HP.

It seems a semi displacement trawler with 671TI's can plane, ut use about 42 gallons an hour combined in doing so. If you simply slow down to hull speed you will improve economy, but to what level I am not sure. I am told that Detroits do not like to run at low rpm for very long and need to be blow out and heated up every hour at least. (give or take and not really my point here) If I de-tune this same boat to run at low rpm hull speed, will the engines give me economy similar to what it would have had with Lehman's? Can Detroit naturals compete in this way? Thanks for any help I m might get. Bill

It seems a semi displacement trawler with 671TI's can plane, ut use about 42 gallons an hour combined in doing so. If you simply slow down to hull speed you will improve economy, but to what level I am not sure. I am told that Detroits do not like to run at low rpm for very long and need to be blow out and heated up every hour at least. (give or take and not really my point here) If I de-tune this same boat to run at low rpm hull speed, will the engines give me economy similar to what it would have had with Lehman's? Can Detroit naturals compete in this way? Thanks for any help I m might get. Bill