docvchulek

Veteran Member

- Joined

- May 22, 2019

- Messages

- 27

- Location

- United States

- Vessel Name

- Fate's Fortune

- Vessel Make

- Monk/Vic Franck

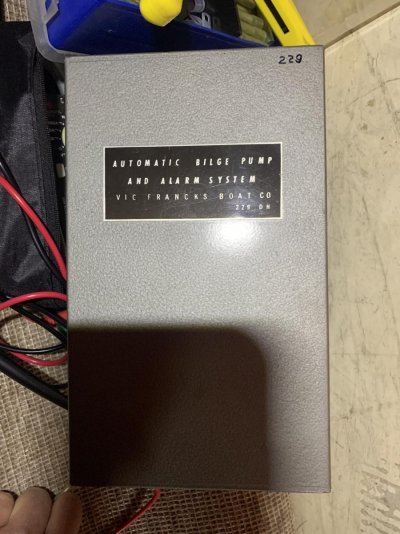

I have a 1971 Monk trawler built by Vic Franck. One of the bilge pumps is no longer working correctly. Specifically, it will pump in manual mode but not in automatic mode.

The float works as designed, and when triggered, the light will come on to indicate that the float was activated, but the pump does not turn on. The light will turn off when I push the reset button at the helm.

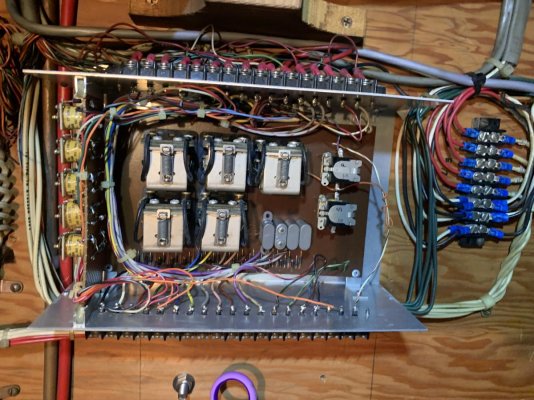

I opened the control box and found that one of the relay switches is stuck in the middle and does not move when pressing the test button as the other four do.

Has anyone worked on this type of control system and knows what type of relay switches these are?

Thanks, Daron

The float works as designed, and when triggered, the light will come on to indicate that the float was activated, but the pump does not turn on. The light will turn off when I push the reset button at the helm.

I opened the control box and found that one of the relay switches is stuck in the middle and does not move when pressing the test button as the other four do.

Has anyone worked on this type of control system and knows what type of relay switches these are?

Thanks, Daron