paulga

Guru

- Joined

- May 28, 2018

- Messages

- 1,030

- Location

- United States

- Vessel Name

- DD

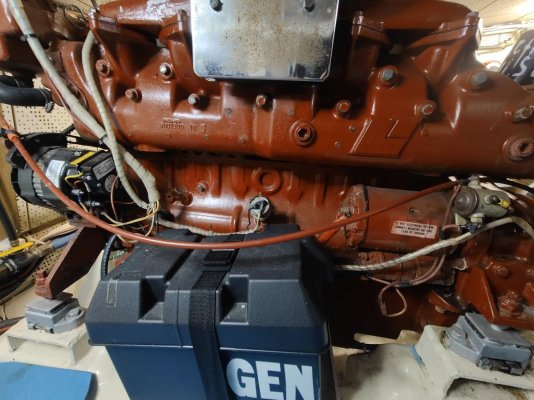

- Vessel Make

- Marine Trader Sundeck 40'

for preparing the engine room for liveaboards the winter (temp generally is lowest for 2 weeks in Feb), is it sufficient to leave the water heater on? or should it be completed with a bilge heater e.g. twin hornet 700w or a oil filled heater?

I saw people frequently mention an engine block heater, but couldn't find an exact model in my search. could you recommend such a block heater?

I saw people frequently mention an engine block heater, but couldn't find an exact model in my search. could you recommend such a block heater?