boaterholic

Veteran Member

- Joined

- Jul 6, 2022

- Messages

- 32

I have started getting holding tank, smells inside the boat over the last few days, I’m sure, because the two heads were being used while the boat was being delivered to its new home.

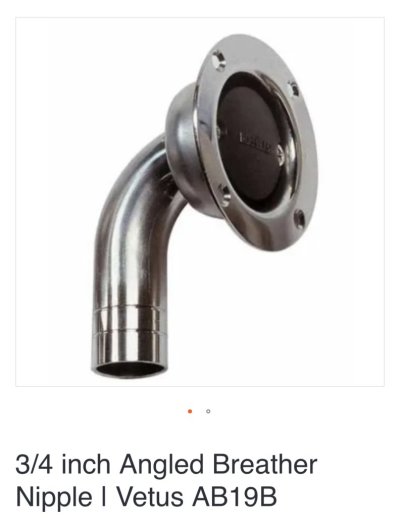

I am suspicious of the vent line. Can anyone tell me if I disconnect the line from the through hall? Should I be able to blow backwards into the tank without restriction?

I have tried removing the charcoal filter from the line, and it is not plugged up as I can blow through it in either direction. Also, I can blow through the line and out the side vent where it would normally vent. However, if I try blowing through the line and into the tank, I cannot blow into the tank. I assume this is not normal as I would imagine when you are being pumped out, he needs to be able to vent into tank.

I can access the vent sitting on the top of the tank. But before I did, I wanted to ask here on the forums, if that would be the next step in troubleshooting.

Thank you

I am suspicious of the vent line. Can anyone tell me if I disconnect the line from the through hall? Should I be able to blow backwards into the tank without restriction?

I have tried removing the charcoal filter from the line, and it is not plugged up as I can blow through it in either direction. Also, I can blow through the line and out the side vent where it would normally vent. However, if I try blowing through the line and into the tank, I cannot blow into the tank. I assume this is not normal as I would imagine when you are being pumped out, he needs to be able to vent into tank.

I can access the vent sitting on the top of the tank. But before I did, I wanted to ask here on the forums, if that would be the next step in troubleshooting.

Thank you