Simi 60

Guru

- Joined

- Jul 1, 2016

- Messages

- 5,482

- Location

- Australia

- Vessel Make

- Milkraft 60 converted timber prawn trawler

I have the opportunity to get a Balmar 24v J180 mount alt

https://balmar.net/product/9504-24-140-ig/

And a MC 624 regulator, looking near new for the right price.

Whilst the blurb says the MC 624 "Now includes lifepo4"

https://balmar.net/product/mc-624/

further digging shows "partial" (scroll down link)

https://balmar.net/balmar-technology/multi-stage-regulation/

What does this mean to me?

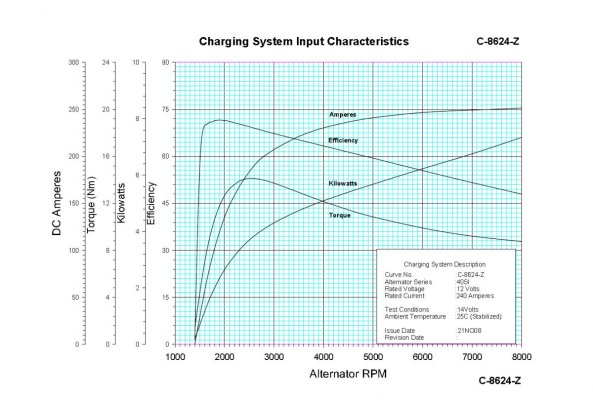

ALSO, seeing as we only run at around 1150rpm, what sort of output would we realistically expect from this?

I am thinking I'd be busting off the pulley on my 40amp Delco and installing it on this?

Thanks

https://balmar.net/product/9504-24-140-ig/

And a MC 624 regulator, looking near new for the right price.

Whilst the blurb says the MC 624 "Now includes lifepo4"

https://balmar.net/product/mc-624/

further digging shows "partial" (scroll down link)

https://balmar.net/balmar-technology/multi-stage-regulation/

What does this mean to me?

ALSO, seeing as we only run at around 1150rpm, what sort of output would we realistically expect from this?

I am thinking I'd be busting off the pulley on my 40amp Delco and installing it on this?

Thanks

Last edited: