Jeff F

Guru

- Joined

- Nov 5, 2015

- Messages

- 2,437

- Location

- Canada

- Vessel Name

- Escapade

- Vessel Make

- 50` US Navy Utility trawler conversion

My new boat has a 2015 motor. It was one of the things that drew me to the boat originally. I had followed OC Diver's repower, and our boats and use cases are broadly similar. It seems like the perfect power system for me.

I've now had a proper sea trial. Ran at 1600-1800 rpm for 24 hours, then a day of playing around including some time at maximum output. I've got a little bit of shaft rumble at the higher end of that range, but not concerning. Will check alignment this winter.

I checked all the fluid levels before launching, but then happily handed over the ER to a friend helping me on the delivery who is an ex merchant marine oiler. He added a bit of oil at the end, but it might have been low by his standard from the get go. Everything seems to operate as it should. We're trapping a lot of gunk in the fuel filters but I'll burn through it, I think. Have a good supply of filters.

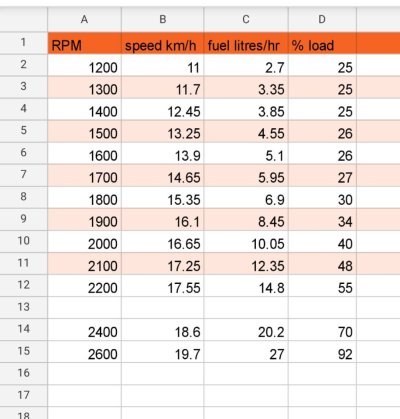

I'm pretty sure I'm overpropped. I was interested in advance in the %load instrumentation, and curious about what it was actually going to tell me. The boat is 50', all water line, maybe 35,000 displacement. Very easily driven up to 8 knots, and I think my target open water cruising speed will be 7-8 knots, something like 1500 rpm. In my current thinking I can live happily with the existing prop.

More details:

- max rpm was ~2200 rpm. Uncalibrated, but I have an optimistic view of the instrumentation. I think it's about as good as you can get in a tier 2. I'll do a high idle test some time.

- exhaust extremely clean up to >2100 rpm

- reported %load was 20-30 across the 1500-2000 rpm range, then increased to 100% at WOT.

- at full throttle heavy black smoke. Backing off to 95% load - maybe 50 rpm - eliminated the smoke

- I had black exhaust water at %load > 90. I didn't find this too alarming. Had similar behaviour in a small Yanmar in my sailboat and it was carbon buildup in the exhaust manifold. The boat has not seen high load operation in the last ten years, if ever.

Comments? Advice? Observations? Will be playing in the ER this winter after another month of waterway cruising. Thinking about soundproofing and ER ventilation, which is currently non-existent. But that's for another thread.

I've now had a proper sea trial. Ran at 1600-1800 rpm for 24 hours, then a day of playing around including some time at maximum output. I've got a little bit of shaft rumble at the higher end of that range, but not concerning. Will check alignment this winter.

I checked all the fluid levels before launching, but then happily handed over the ER to a friend helping me on the delivery who is an ex merchant marine oiler. He added a bit of oil at the end, but it might have been low by his standard from the get go. Everything seems to operate as it should. We're trapping a lot of gunk in the fuel filters but I'll burn through it, I think. Have a good supply of filters.

I'm pretty sure I'm overpropped. I was interested in advance in the %load instrumentation, and curious about what it was actually going to tell me. The boat is 50', all water line, maybe 35,000 displacement. Very easily driven up to 8 knots, and I think my target open water cruising speed will be 7-8 knots, something like 1500 rpm. In my current thinking I can live happily with the existing prop.

More details:

- max rpm was ~2200 rpm. Uncalibrated, but I have an optimistic view of the instrumentation. I think it's about as good as you can get in a tier 2. I'll do a high idle test some time.

- exhaust extremely clean up to >2100 rpm

- reported %load was 20-30 across the 1500-2000 rpm range, then increased to 100% at WOT.

- at full throttle heavy black smoke. Backing off to 95% load - maybe 50 rpm - eliminated the smoke

- I had black exhaust water at %load > 90. I didn't find this too alarming. Had similar behaviour in a small Yanmar in my sailboat and it was carbon buildup in the exhaust manifold. The boat has not seen high load operation in the last ten years, if ever.

Comments? Advice? Observations? Will be playing in the ER this winter after another month of waterway cruising. Thinking about soundproofing and ER ventilation, which is currently non-existent. But that's for another thread.