TheAtomicDog

Senior Member

- Joined

- Oct 30, 2020

- Messages

- 157

- Vessel Name

- Salty Seagull

- Vessel Make

- SSP Type 211

Hey guys,

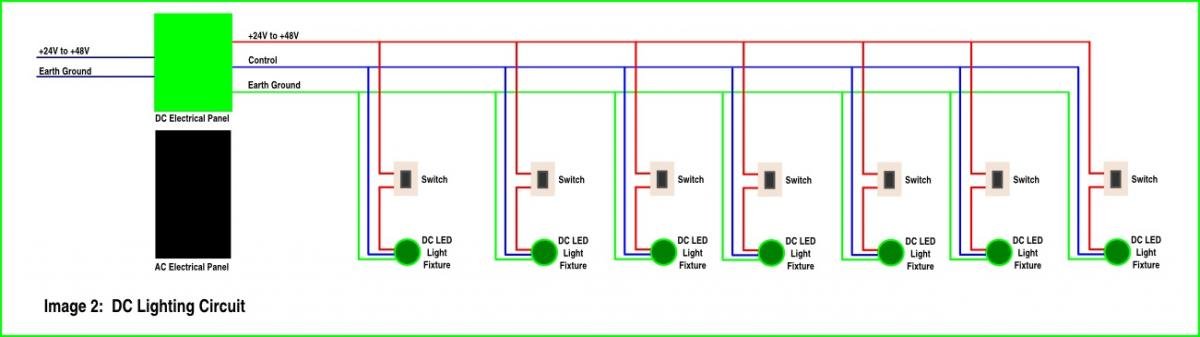

I am rewiring my boat from scratch. I have 4 DC lights in the forward cabin and 2 AC lights. This is about 5-6 meters from the panels. Assuming I run 1 wire from the panel for DC and one for AC into the main cabin, what is the right way to split them for the individual lights?

Thanks!

I am rewiring my boat from scratch. I have 4 DC lights in the forward cabin and 2 AC lights. This is about 5-6 meters from the panels. Assuming I run 1 wire from the panel for DC and one for AC into the main cabin, what is the right way to split them for the individual lights?

Thanks!