RobClipper30

Member

- Joined

- Dec 22, 2020

- Messages

- 13

Hi folks,

Have a problem and thought I’d turn to the collective wisdom of the group for some advice.

New purchase of 40 year old Clipper Flybridge 30ft with the original Ford Lehman 80 HP Diesel.

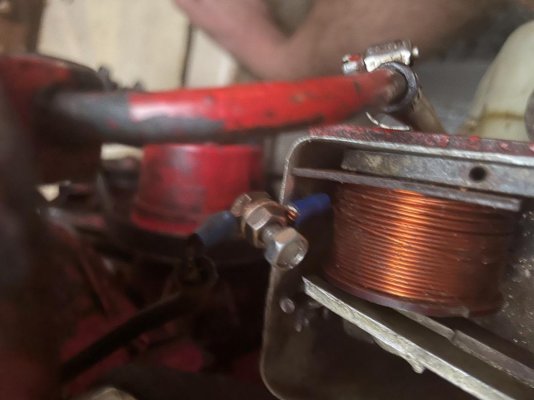

Electric stop doesn’t work, I can see the arm move a little but it can’t seem to make it all the way so I have to lift the saloon floor and pull it manually each time.

Photo attached. Sorry it’s not great resolution.

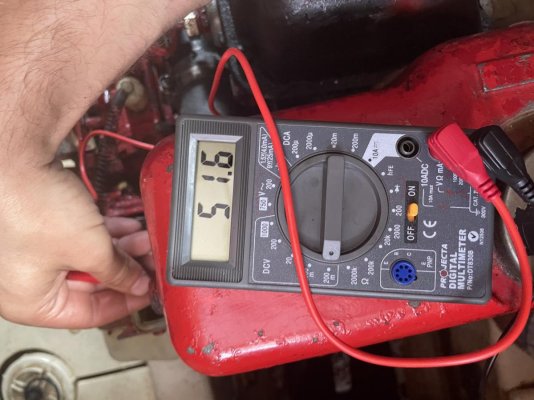

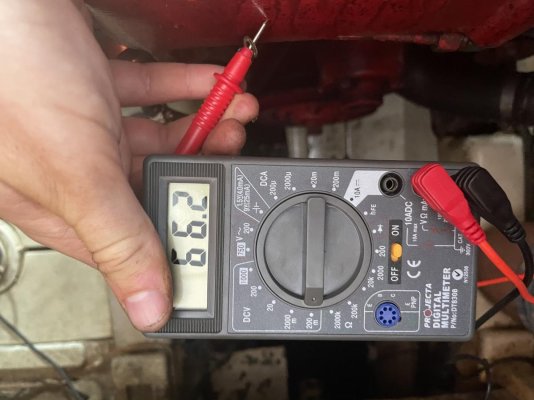

Guessing it’s the Solenoid (the white thing?) Battery levels is at full capacity so assuming it’s not power related but haven’t confirmed with voltmeter or anything.

Keen to see if I can fix it myself but have to preface this by saying I’m completely green / novice at all things mechanical but I’m eager to learn if someone can point me in the right direction!

Have a problem and thought I’d turn to the collective wisdom of the group for some advice.

New purchase of 40 year old Clipper Flybridge 30ft with the original Ford Lehman 80 HP Diesel.

Electric stop doesn’t work, I can see the arm move a little but it can’t seem to make it all the way so I have to lift the saloon floor and pull it manually each time.

Photo attached. Sorry it’s not great resolution.

Guessing it’s the Solenoid (the white thing?) Battery levels is at full capacity so assuming it’s not power related but haven’t confirmed with voltmeter or anything.

Keen to see if I can fix it myself but have to preface this by saying I’m completely green / novice at all things mechanical but I’m eager to learn if someone can point me in the right direction!