- Joined

- Nov 8, 2012

- Messages

- 2,315

- Location

- USA

- Vessel Name

- Sandpiper

- Vessel Make

- Bluewater 40 Pilothouse Trawler

I phoned March. They have this one for list $318USD:

https://www.marchpump.com/pump/815-pl-beer-magnetic-drive-pump/

and a Stainless version

https://www.marchpump.com/pump/815-ss-c-beer-magnetic-drive-pump/

I have to go through a distributor and they found one in North Vancouver one for me.

It turns out they have the 4 of the SS version in stock and are willing to sell at a 15% discount as she wants to move out the stock. Price would be $359 USD which suits me just fine.

I'm going to give this a whirl, plumb it up, put it through some baby-step tests and watch temperatures carefully with a pyrometer.

Jim

That's a pretty good price. My distributor wants $323 US in Seattle.

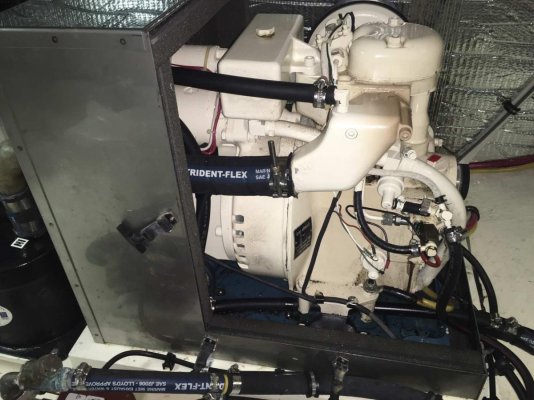

Viewing the picture, the placement of the major components ..... Looks just like my NL

Viewing the picture, the placement of the major components ..... Looks just like my NL