I would like to know more about replacing the window sliders. I had the cracked windows replaced in the aft cabin and after I drydocked the boat, they cracked again!

I've been meaning to do a writeup on these. They arent fun

And I would recommend just doing one at a time. I tried to do all of them at once and it sucked. However, I was trying to get them done before painting started.

For the sliders the basics are as follows:

- you need to remove the interior wood trim above and below the windows to get access to the interior fasteners. that will take you 2-3hrs to remove all the bungs.

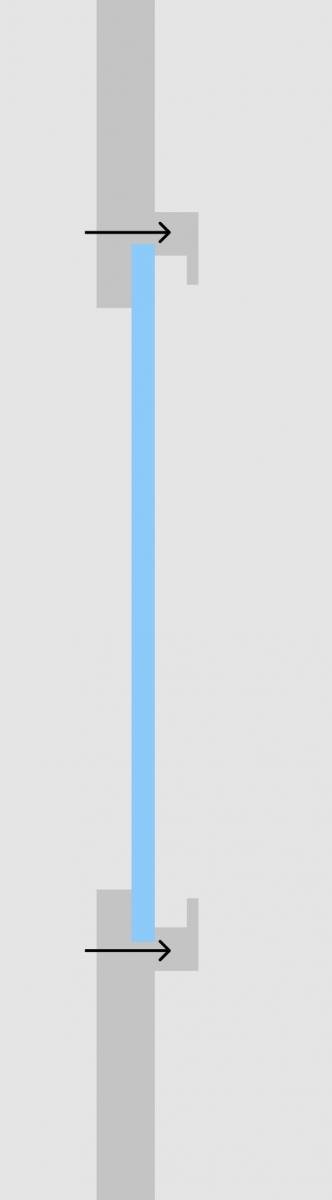

- the interior fasteners go horizontal, above and below the windows. the exterior fasteners go vertical.

- to access the exterior fasteners you need to scrape the window frames to find the bungs. there are probably around 12 on the outside.

- the interior fasteners are semi-hidden with some fairing compound, but you can typically see the outlines of them. I chipped out the compound. there are about 18 of these per window.

- you then need to break the sealant around the exterior frames. I used the edge of a wood chisel for this and just ran it around the edges.

- then remove all the fasteners. they are bronze, so do it by hand so you dont strip them. they cost about $2 a piece to replace.

- use a putty knife to pry under the exterior frame and slowly remove it. be careful and have two sets of hands here. the frame, window tracks and slider window all come out as one piece (if you are lucky).

- the fixed frame then can just be pulled straight out. be careful with that as it can fall out when you remove the frame.

- the wood frame is a bit flexible when you take it out, so if you pull the horizontal frames (gently) you can pull the window out of the track.

- then carefully remove the metal tracks. my screws were all corroded so I used a multitool and just cut them. DONT DESTROY these during removal. you need them to as templates to cut the new ones.

- then sand and prep the frames for new tracks. the most time will be spent here.

- I sanded down to bare wood and then had a lot of repair to do with systemthree fairing epoxy. I wouldn't recommend that, unless you have just some small areas to fix. I would just get new frames milled. it will save you a ton of time and you will get better results.

- then prep the frame on the superstructure. it looks like its all rotten when you first take the frames off. but thats just the old dolphinite. scrape and sand all that off then use penetrating epoxy, build any areas up with fairing epoxy, then prime.

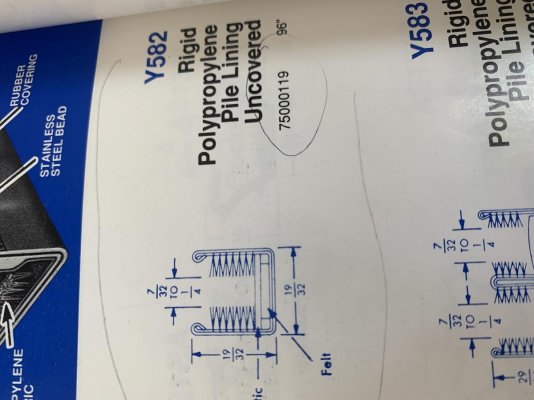

- then you need to get 6 X 8" stanpro window tracks. that will give you enough for all 4 sliders in the boat. you also need 1x 8" single track for the vertical felt between the sliders and fixed frames.

- if you need to replace the windows they are just laminated safety glass. I replaced 7 and it was only $500. but - MAKE SURE to have the shop sand the edges of the windows down, or do it yourself with 120. if you dont, the rough edges will gouge into the window tracks.

- cut the window tracks using your old ones as the template. use an angle grinder to cut the tracks to the basic size, then use a flap disk sanding wheel to trim to down perfectly. it makes quick work of it. we would test fit the tracks and mark any overlap with a pen, then grind down to that line.

- then install 900 tiny screws to hold the vertical and top track in place. you need to pre-drill these with a metal drill bit. I didnt use screws on the bottom track, as recommended by others. I bedded all of them with sikaflex.

- then drill the drain holes in the bottom track.

- I used butyl to hold the fixed frames in place but found it too thick for the main frames. I used sika for that.

- you need 2-3 people to install the window. dont try to be the solo hero. I did and shattering one of the windows on install when the frame imploded. it was the low point of the project.

I have pictures of most every step I can share. Ping me with any questions.