danderer

Guru

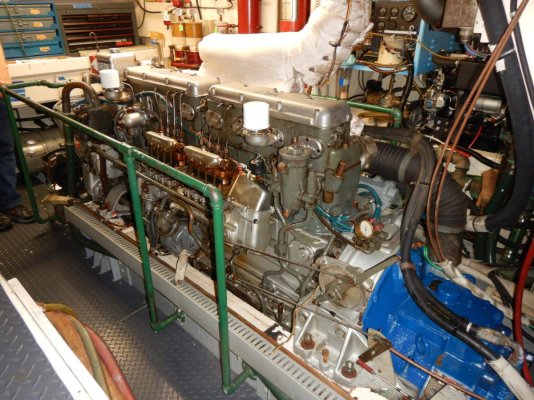

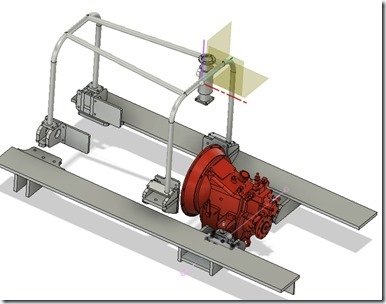

I want to add some SS railings around the engine. Without them I find myself steadying myself by grabbing or touching things I shouldn't - especially when underway.

I expect pretty much any fabricator can do this, right? Any recommendations in the Baltimore/Annapolis area?

..or any better ideas?

I expect pretty much any fabricator can do this, right? Any recommendations in the Baltimore/Annapolis area?

..or any better ideas?