Bruce Palmer

Member

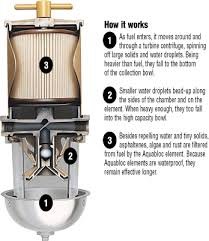

I have been writing this for two years in my head, but wanted to exhaust every troubleshooting skill I have (not much evidently) before posting.* Our boat has two John Deere 4045 engines with standard primary and secondary engine* fuel filters, supplied by the standard Racor 500 series dual manifold turbine fuel filter (Racor) with selector valve and vacuum gauge, supplied by a keel “day tank” about 3-4 feet below the engine.* We also have a fuel polishing pump and enough valving / piping flexibility to pump / pressurize wherever we need to.

Because the day tank is below the engine and filters, there is a small 2*+- psi vacuum in the fuel lines when the engines are off.* I learned early in our ownership that after leaving the boat for a week or two the port engine would start, run for about 10 seconds, then die (perhaps about the right time air in the secondary filter could*get to the injector pump).* I would then need to bleed the engine secondary filter to get things started.* So I went through all lines, pressurized and looked for fuel leaks, and replaced a suspect gasket or two.* Nothing changed.* I then started closing the ball valve feeding the engine from the Racor 500 thinking this would eliminate the vacuum and thus air infiltration.* Nothing changed.* So I started using our polishing pump to pressurize the fuel lines and this helped and now no problems leaving the port engine for a month or so.* Inconvienent, but at least I had a work-around.

So, last fall I had my work around in play after the boat sat for about 6 weeks and there was still about 1/2 psi positive pressure in the lines (pressure very slowly leaks off over time).* I open all the valves, hit the starter, and it runs for 1 second or so.* Doesn't want to restart.* I am able to restart by pressurizing*the fuel line to about*3 psi for a 10 second crank.* This is the first time it has quit after 1 second.

Here is what I know:

-The engines always start immediately*- like the first cylinder.

-I've tried feed from both sides of the Racor 500 thinking gasket leak, no difference. Replaced all gaskets. No change.

-In fuel lines/fittings air can pass through very tiny leaks when fuel might not.* Or, just because I can't find fuel seeping out at 2 psi does not mean that air might be leaking in at -2 psi vacuum.

-If fuel line pressure can be maintained at even a very small psi in the lines no air can seep in.* Right?* Right???

-The starboard engine does not have the same problem unless left for 6 months or so.

-I'm really frustrated.

Has anyone else chased air like this, and did you finally find out what was going on?* I'm to the point I will need to call the John Deere mechanic, but they are located 4 hours (round trip) away and I hate not being able to figure out what should be a simple problem / solution.* Also, what would they do that I have not tried already?

Because the day tank is below the engine and filters, there is a small 2*+- psi vacuum in the fuel lines when the engines are off.* I learned early in our ownership that after leaving the boat for a week or two the port engine would start, run for about 10 seconds, then die (perhaps about the right time air in the secondary filter could*get to the injector pump).* I would then need to bleed the engine secondary filter to get things started.* So I went through all lines, pressurized and looked for fuel leaks, and replaced a suspect gasket or two.* Nothing changed.* I then started closing the ball valve feeding the engine from the Racor 500 thinking this would eliminate the vacuum and thus air infiltration.* Nothing changed.* So I started using our polishing pump to pressurize the fuel lines and this helped and now no problems leaving the port engine for a month or so.* Inconvienent, but at least I had a work-around.

So, last fall I had my work around in play after the boat sat for about 6 weeks and there was still about 1/2 psi positive pressure in the lines (pressure very slowly leaks off over time).* I open all the valves, hit the starter, and it runs for 1 second or so.* Doesn't want to restart.* I am able to restart by pressurizing*the fuel line to about*3 psi for a 10 second crank.* This is the first time it has quit after 1 second.

Here is what I know:

-The engines always start immediately*- like the first cylinder.

-I've tried feed from both sides of the Racor 500 thinking gasket leak, no difference. Replaced all gaskets. No change.

-In fuel lines/fittings air can pass through very tiny leaks when fuel might not.* Or, just because I can't find fuel seeping out at 2 psi does not mean that air might be leaking in at -2 psi vacuum.

-If fuel line pressure can be maintained at even a very small psi in the lines no air can seep in.* Right?* Right???

-The starboard engine does not have the same problem unless left for 6 months or so.

-I'm really frustrated.

Has anyone else chased air like this, and did you finally find out what was going on?* I'm to the point I will need to call the John Deere mechanic, but they are located 4 hours (round trip) away and I hate not being able to figure out what should be a simple problem / solution.* Also, what would they do that I have not tried already?

Last edited:

especially if you don't know the age of the hose. Those rubber hoses are necessary in order to isolate vibration between the engine and the rest of the boat, but often they look perfect, but are deteriorated, as mentioned in an earlier post. Replace it, and while you're at it, replace the same hose on the other engine at the same time! Please keep us advised as to what you do and what happens. Take care, and good luck!

especially if you don't know the age of the hose. Those rubber hoses are necessary in order to isolate vibration between the engine and the rest of the boat, but often they look perfect, but are deteriorated, as mentioned in an earlier post. Replace it, and while you're at it, replace the same hose on the other engine at the same time! Please keep us advised as to what you do and what happens. Take care, and good luck!