I'll presume "Awlgrip" means painting?

If your present finish is intact, e.g. NO water intrusion, no discoloration at cracks, no peeling, then painting might be an option. If the existing finish has flaws, they will need to be repaired regardless of the end finish. Prep is prep, and I'd propose that the prep will be the same no matter. Paint may last longer, but not if you don't prep it correctly.

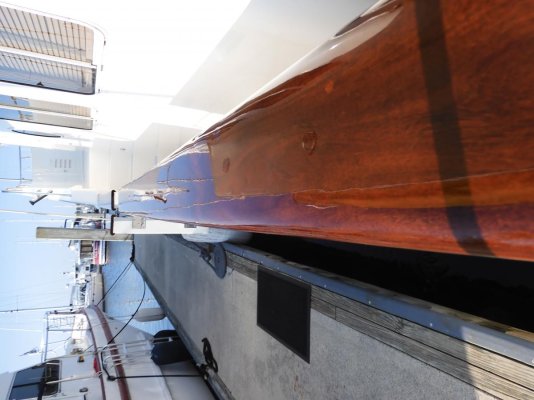

Another option you don't mention is Awlwood vs. traditional varnish, and what final finish you want to achieve. If you want the beauty of a varnished caprail, Awlwood is an option that will last the longest, but it requires "wooding" of the surface: you have to get to bare wood to properly apply the Awlwood "system". I had been using Epifanes for years; beautiful result, but in the semi-tropical environment of the south, it required refreshing every 6-9 months. Let it go too long, and the finish starts to fail and then it's back to wood. The Awlwood system will last much longer, is faster to apply, but either requires the same amount of prep. As OC mentioned, if you want the paint to last, encapsulation is part of that paint prep that's not part of varnish or Awlwood prep. I'm much happier with the Awlwood over Epifanes. Highly recommend it. If your teak is dark, the clear primer may be a better choice. I used the "yellow" primer, and it darkened the wood more than it needed to be.

It boils down to personal preference. I wouldn't be at all happy with a painted caprail; for me, it covers up the natural beauty of the wood. But that's me!