Nomad Willy

Guru

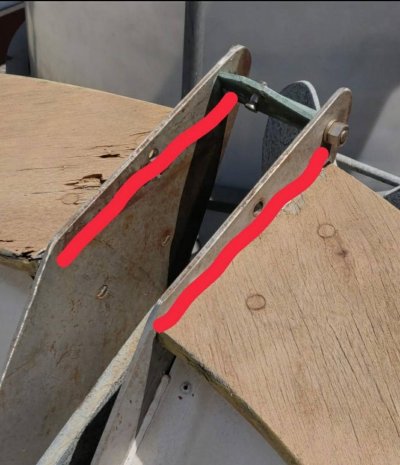

There’s a bronze anchor line guide at the top of the bow of my W30 that appears to be held in place by two flat head, countersunk straight slot bolts.

The heads of the bolts are about 1” in diameter. The last time I looked (or tried to look) I didn’t see the nuts. I have no screw driver even close to that size.

I want to do some serious machining on the top of this unit. Can one get a socket on the nut? I can make something to work as a screw driver.

Anybody ever remove these bolts?

What do you call it? A bow chock?

The heads of the bolts are about 1” in diameter. The last time I looked (or tried to look) I didn’t see the nuts. I have no screw driver even close to that size.

I want to do some serious machining on the top of this unit. Can one get a socket on the nut? I can make something to work as a screw driver.

Anybody ever remove these bolts?

What do you call it? A bow chock?

Last edited: