Esheuwfelt,

Others here may be better able to reason about this than me. I'd stay tuned to see if there are better replies.

I have a really hard time thinking about fuel efficiency from rpm alone. If an engine is propped more aggressively, the load on the engine will be higher at the same rpm than if less so. Think about it this way, would you expect your car to use more or less fuel at 2000rpm going up or down a steep hill? In one case the hill helps spin the engine, in the other it fights it. Then there is the space in between.

When it comes to moving a boat through water, just like moving a car through air, I suspect it is the air/water resistance that matters most.

In other words, even if an engine might, in isolation, be more energy efficient at a higher rpm, moving a boat at a faster speed seems less likely to be less efficient.

Tuning the gearing and prop to the desired cruise speed seems like it would help, but I can't say I have the data to do that on these engines. I usually just tune the props such that the engine performs sensibly across the full range of throttle (low vessel speed at idle speed, makes at least close to WOT rpms at WOT, doesn't make blacknorbdark smoke, except,possibly, very briefly on hard acceleration). Then I assume I am close to good.

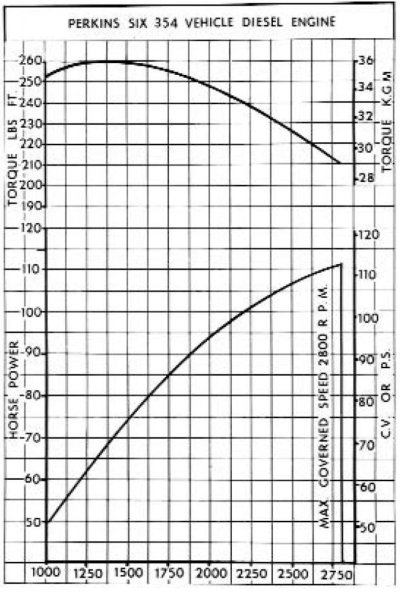

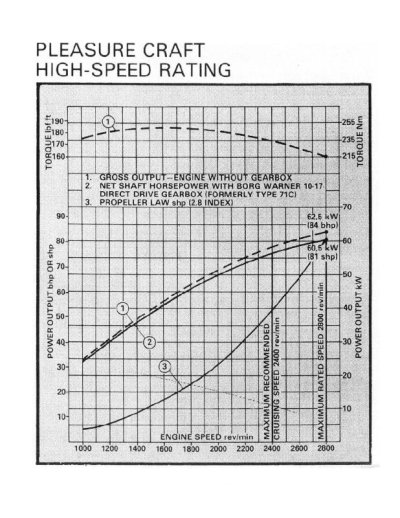

If I really knew I'd never want more power, I might over prop a little to lower rpms at cruise to get cruise closer to that torque sweet spot. But, I just hate tovmess with things like that too much, personally.

Basically, I just try to make sure my engines start quickly, cruise no leaa than somewhere near peak on the rpm torque curve and run clean, in the normal temp range, and smooth with good oil pressure.

Again, there are others here with much more experience and intuition about these things than me.