Mtcabsales

Member

So I have a couple of questions on running my Perkin's diesel engines.

According to TF member Greg, I have these below decks:

2-6.354's made in Britain in 1978.

They have about 1200 hours on them, according to the hour meters.

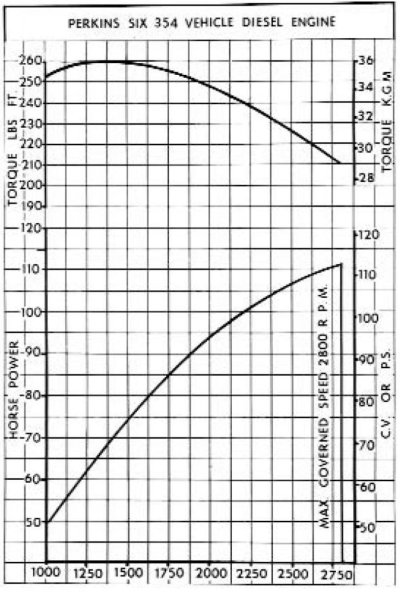

What is the usual RPM to run these engines? I live in the CA Delta, in semi fresh water, and with the tides, I like to run mine at about 1200-1300 RPM for my 34" Californian. This keeps me in the range 7-11 MPH, depending on which way the tide is going; I could go higher, to 1800-2000 RPM, but the noise level increases along with the fuel consumption, and I only seem to get a mile or two an hour gain.

Doesn't seem worth it to me, the engines are working harder, fuel use goes up, etc.

The reason I am asking is because a friend who has a similar boat and engines, says that he typically runs his at 2000-2200 RPM all day, 'because these engines need to run hard to make the last, and running them at lower RPM's is not good for them'.

As I've admitted previously on this forum, I am not an engine head, and only go on my gut instincts, and I think that running an engine harder than I need to, for a mile or two an hour gain, is not what I want to do.

These engines are, in any event, 40 years old, albeit, with relatively few hours on them, but how hard should I actually push them to keep them running for another forty years?

And what about the transmissions?

According to TF member Greg, I have these below decks:

2-6.354's made in Britain in 1978.

They have about 1200 hours on them, according to the hour meters.

What is the usual RPM to run these engines? I live in the CA Delta, in semi fresh water, and with the tides, I like to run mine at about 1200-1300 RPM for my 34" Californian. This keeps me in the range 7-11 MPH, depending on which way the tide is going; I could go higher, to 1800-2000 RPM, but the noise level increases along with the fuel consumption, and I only seem to get a mile or two an hour gain.

Doesn't seem worth it to me, the engines are working harder, fuel use goes up, etc.

The reason I am asking is because a friend who has a similar boat and engines, says that he typically runs his at 2000-2200 RPM all day, 'because these engines need to run hard to make the last, and running them at lower RPM's is not good for them'.

As I've admitted previously on this forum, I am not an engine head, and only go on my gut instincts, and I think that running an engine harder than I need to, for a mile or two an hour gain, is not what I want to do.

These engines are, in any event, 40 years old, albeit, with relatively few hours on them, but how hard should I actually push them to keep them running for another forty years?

And what about the transmissions?