markbarendt

Senior Member

My, new to me boat, came with some really long runs of DC cables, but what do I know?

I had a marine surveyor inspect the boat before buying. the survey basically says, "the electrical systems generally comply with ABYC standards".

Some issues were obvious, some were a bit of a puzzle.

For example the bilge pumps weren't working, bad ground got some action going but still not right, ... They were wired in improperly on the 4 battery bank and only getting 6 volts.

After sorting out the systems a bit to make sure 1, that I generally understood the systems and 2, that the cables were following electrically logical and safe paths and 3, had some confidence the whole thing would not burn down; I decided to run a higher load test.

My microwave was to heat some water using the Xantrex Freedom XC 2000 inverter. The batteries were fully topped up, a bank of 4 Trojan T125's.

The microwave was set to use 1000w of cooking power which means after it's overhead is added it needs just shy of 1200 watts of 120, 10 amps from the inverter.

The microwave ran!

There's always a but though, The battery monitor was showing 188 amps being sucked out of the battery bank, the cables could only get 10.5 volts delivered to the inverter.

That 188 amps is just under the 192 amp input limit of the inverter so I stopped the test fast just after reading the numbers.

I'm skilled enough to be able to guess that the wires were too long, but after down loading the owners manual for the inverter I got a good schooling on inverters and just how bad the installation was botched on this boat.

To start the recommended minimum size battery cables for a 5 foot run are 3/0 to the battery and Chassis ground at 2/0.

WTF? The installed cables, 1/0 at ~20 feet with 10 AWG running to the house bus bar for the chassis ground.

The installed cables, 1/0 at ~20 feet with 10 AWG running to the house bus bar for the chassis ground.

Similarly the starter cable makes about a 50 foot circuit. The bow thruster and windlass have runs way too long also.

If this is anywhere near the norm for a DIY or semi-pro-non-specialist install, it's a wonder more boats don't burn down.

Rant over.

Productive thought follows. To fix this I need to shorten the cables, a lot. That means 1, getting the inverter close to the batteries and 2, moving the batteries around the boat some.

It's a 1977 Ocean Marine 40 foot with a Lehman 120.

So first, I know it's not safe to put an inverter in an engine room with gasoline power but I'm getting the impression that it's ok around diesel power (with a caveat about heat). Is that right?

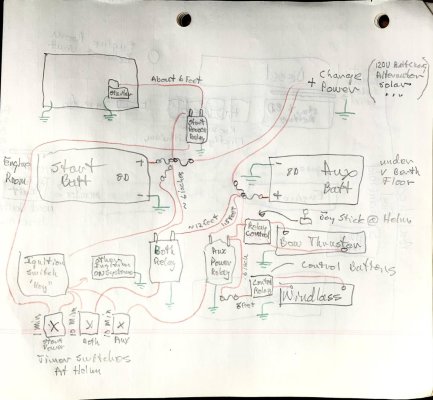

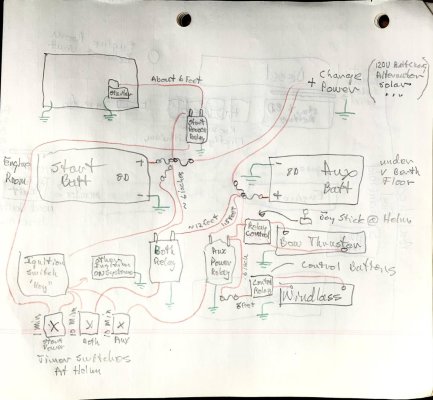

Second, I'm including a hand drawn 'plan' for your educated comment. This plan only deals with the Start and Aux batteries. It gets the aux battery out of the engine room up under the V-berth floor and uses heavy relays to be able to run the heavy cables direct and use control wires for the run to the helm.

Thanks for your help.

I had a marine surveyor inspect the boat before buying. the survey basically says, "the electrical systems generally comply with ABYC standards".

Some issues were obvious, some were a bit of a puzzle.

For example the bilge pumps weren't working, bad ground got some action going but still not right, ... They were wired in improperly on the 4 battery bank and only getting 6 volts.

After sorting out the systems a bit to make sure 1, that I generally understood the systems and 2, that the cables were following electrically logical and safe paths and 3, had some confidence the whole thing would not burn down; I decided to run a higher load test.

My microwave was to heat some water using the Xantrex Freedom XC 2000 inverter. The batteries were fully topped up, a bank of 4 Trojan T125's.

The microwave was set to use 1000w of cooking power which means after it's overhead is added it needs just shy of 1200 watts of 120, 10 amps from the inverter.

The microwave ran!

There's always a but though, The battery monitor was showing 188 amps being sucked out of the battery bank, the cables could only get 10.5 volts delivered to the inverter.

That 188 amps is just under the 192 amp input limit of the inverter so I stopped the test fast just after reading the numbers.

I'm skilled enough to be able to guess that the wires were too long, but after down loading the owners manual for the inverter I got a good schooling on inverters and just how bad the installation was botched on this boat.

To start the recommended minimum size battery cables for a 5 foot run are 3/0 to the battery and Chassis ground at 2/0.

WTF?

Similarly the starter cable makes about a 50 foot circuit. The bow thruster and windlass have runs way too long also.

If this is anywhere near the norm for a DIY or semi-pro-non-specialist install, it's a wonder more boats don't burn down.

Rant over.

Productive thought follows. To fix this I need to shorten the cables, a lot. That means 1, getting the inverter close to the batteries and 2, moving the batteries around the boat some.

It's a 1977 Ocean Marine 40 foot with a Lehman 120.

So first, I know it's not safe to put an inverter in an engine room with gasoline power but I'm getting the impression that it's ok around diesel power (with a caveat about heat). Is that right?

Second, I'm including a hand drawn 'plan' for your educated comment. This plan only deals with the Start and Aux batteries. It gets the aux battery out of the engine room up under the V-berth floor and uses heavy relays to be able to run the heavy cables direct and use control wires for the run to the helm.

Thanks for your help.