Hi All,

My wife and I just got a Camano 31 Troll. Old but is in good shape.

Unfortunately, I am having issues with the fuel gauges. The tanks are 18 W x 44L x 14"H (external values). This equates to 48 USgal.

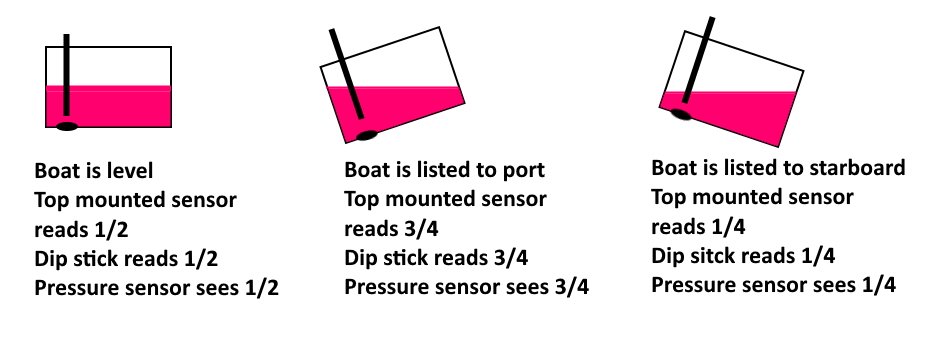

measuring with a wooden dowel rod I can measure the levels on both tanks. But the math (volumes based on stick readings) doesn't match with the gauges readings.

The port reading is stable but the starboard oscillates - sometime too much. One tech had mentioned the send might be bad and to replace is very crazy expensive - no access.

Noticed too that with engine running the levels on gauge are a bit higher.

Ex: stick reading 6.25" that would define a volume of 4950 in3 which is 0.446 ration of the full tank. But the gauge shows 1/4" ... maybe a bit above. Well 0.446 is almost 50% ... half tank!

Help here:

Options on fuel sender and metering?

How non accurate can the stick reading be?

Thank you all

My wife and I just got a Camano 31 Troll. Old but is in good shape.

Unfortunately, I am having issues with the fuel gauges. The tanks are 18 W x 44L x 14"H (external values). This equates to 48 USgal.

measuring with a wooden dowel rod I can measure the levels on both tanks. But the math (volumes based on stick readings) doesn't match with the gauges readings.

The port reading is stable but the starboard oscillates - sometime too much. One tech had mentioned the send might be bad and to replace is very crazy expensive - no access.

Noticed too that with engine running the levels on gauge are a bit higher.

Ex: stick reading 6.25" that would define a volume of 4950 in3 which is 0.446 ration of the full tank. But the gauge shows 1/4" ... maybe a bit above. Well 0.446 is almost 50% ... half tank!

Help here:

Options on fuel sender and metering?

How non accurate can the stick reading be?

Thank you all