nmuir

Senior Member

I have a new-to-me boat with twin Lehmans. I am looking to get some input/comments from the community as experienced Lehman mechanics are hard to find in Mataró Spain where the boat is! I will keep trying to track one down but in the interim am attempting to do some initial diagnostics from afar (I am over 5,000 miles away from the boat now).

The engines have an estimated 5,000+ hours on them (no meters) so there is a distinct possibility they need quite a bit of work.

I include a link to a short video of the port engine. https://youtu.be/BgEwBLKqLqk This is from when the engine was started from cold, so unless there is no thermostat in the engine the header tank coolant should be still. It isn't.

You can see the coolant is murky, and with the bubbles I am thinking that the head gasket is gone. The engine oil is ok.

I also wonder about the knocking and worry it is piston slap. It is definitely from the front of the engine (ie near cylinder 1 not 6). It may be hopeful thinking but could a shot head gasket or mis-adjusted valve train make that much knocking?

*If* it is piston slap do you think that the engine is about to expire? I have heard some people say Lehamns can run for quite a while with piston slap.

I have heard some people say Lehamns can run for quite a while with piston slap.

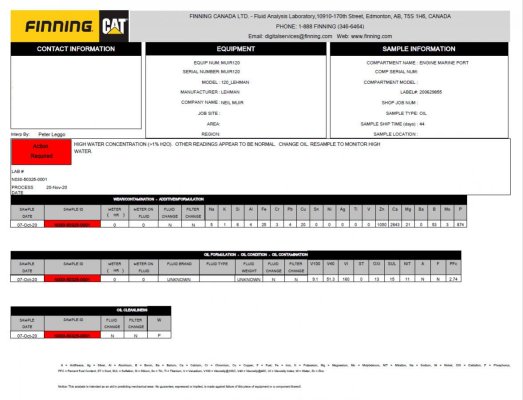

Oil samples should be back in about 4 weeks - the longer turnaround due to covid.....

Helpful comments from those with experience are welcome! Thanks in advance.

The engines have an estimated 5,000+ hours on them (no meters) so there is a distinct possibility they need quite a bit of work.

I include a link to a short video of the port engine. https://youtu.be/BgEwBLKqLqk This is from when the engine was started from cold, so unless there is no thermostat in the engine the header tank coolant should be still. It isn't.

You can see the coolant is murky, and with the bubbles I am thinking that the head gasket is gone. The engine oil is ok.

I also wonder about the knocking and worry it is piston slap. It is definitely from the front of the engine (ie near cylinder 1 not 6). It may be hopeful thinking but could a shot head gasket or mis-adjusted valve train make that much knocking?

*If* it is piston slap do you think that the engine is about to expire?

Oil samples should be back in about 4 weeks - the longer turnaround due to covid.....

Helpful comments from those with experience are welcome! Thanks in advance.