DLETF

Veteran Member

- Joined

- Sep 28, 2017

- Messages

- 48

- Location

- USA

- Vessel Name

- Buster

- Vessel Make

- North Sea Cape Classic 30

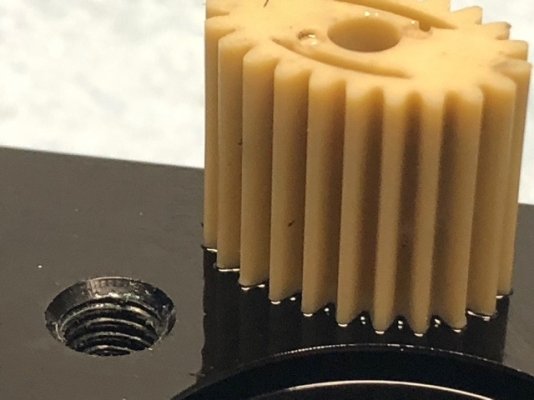

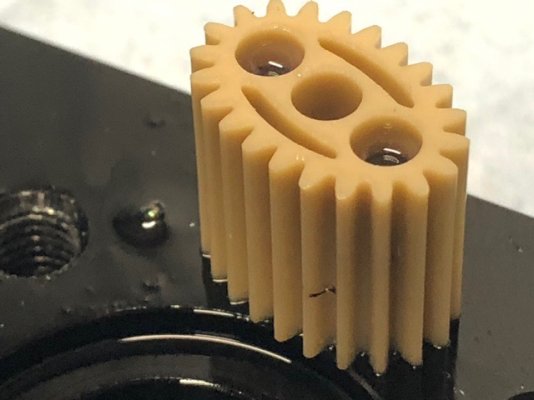

I installed Optio fuel flow sensors in the supply and return fuel lines of my Cummins 6BT 5.9-M engine about 6 months ago. The sensors functioned properly until the last cruise when the GPH usage shown on the iPhone app suddenly increased several fold without a change in the throttle. The return fuel line sensor was shipped to the factory. Three photos attached to this post demonstrate debris in the sensor gears. The longer, thinner debris in the first and third photos are composed of a ferrous metal. No fuel system or engine work has been performed since the flow sensors were installed.

I plan to install a 20 micron filter in the return fuel line just before the return flow sensor.

Questions:

1. What is the source of the debris?

2. Are the metallic debris a symptom of a serious engine condition?

Thanks

I plan to install a 20 micron filter in the return fuel line just before the return flow sensor.

Questions:

1. What is the source of the debris?

2. Are the metallic debris a symptom of a serious engine condition?

Thanks