NightCrawler

Senior Member

- Joined

- Feb 17, 2016

- Messages

- 211

- Location

- USA

- Vessel Name

- Previous owner GB 42 Classic

- Vessel Make

- Currently running a 23' CC

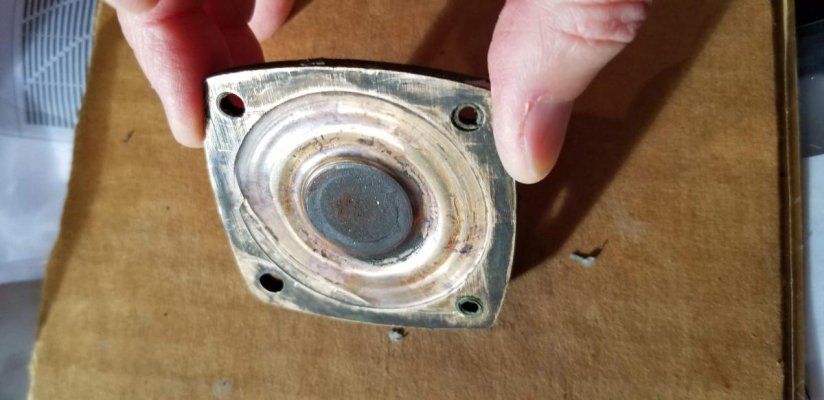

1990 Onan with 202M11 raw water pump. Quit pushing water. New impeller, old was torn, not wrecked. New impeller, will not lift water to the pump. Sea cock is clean, new hose on intake and raw water system last year. Clamps tight. I can see the impeller moving around with both discharge ant intake hoses off. No instructions. Back filled the system from the exhaust cooling hose to prime it (although the lift is less than a foot) nada. She will not pull water.

Sounds like an air leak and we've run it all summer with zero issues. Can the pump housing be cracked, allowing air? Baffled.

Sounds like an air leak and we've run it all summer with zero issues. Can the pump housing be cracked, allowing air? Baffled.