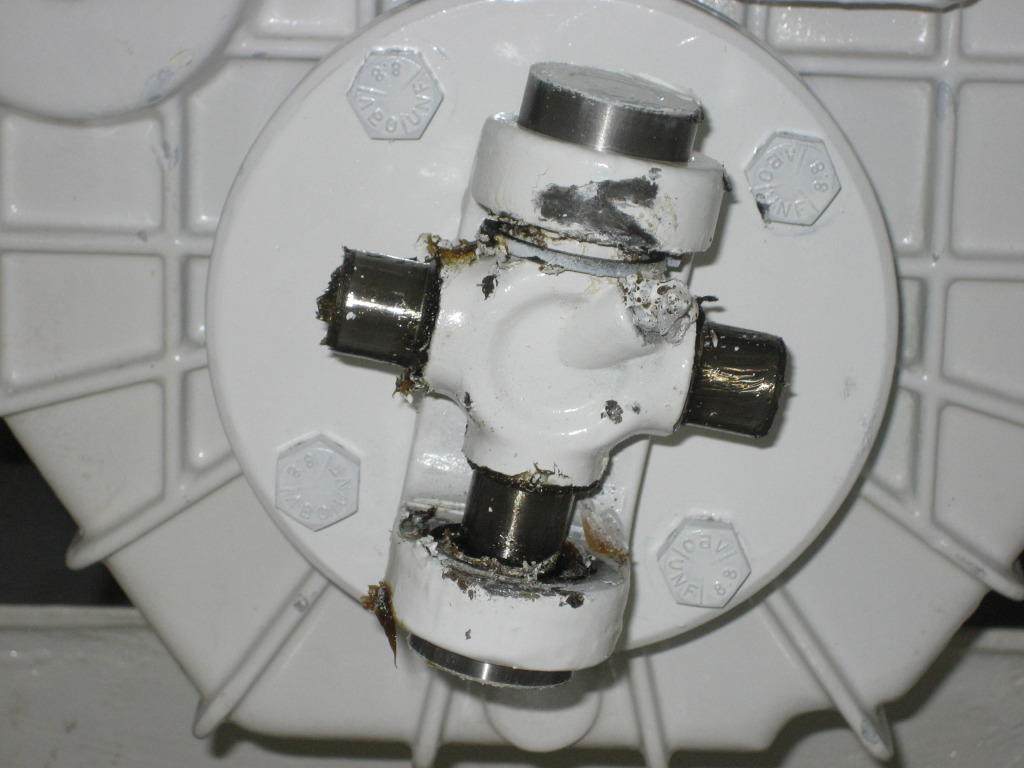

Pictured is a typical automotive/agricultural u-joint. There are two types of retainers shown, the split ring with holes in the end tabs and the split ring without holes.

The bearing cups are removed from the ends of the cross, the cross inserted into the two yokes, and the bearing cups inserted/pressed into the yokes from the outside. Inside the bearing cups are needle roller bearings. After the cups are pressed far enough into the yokes, the split rings are inserted into grooves to hold the bearing cup in place. If a needle falls away from the cups outer wall, it can lodge in the bottom of the cup,preventing the cup from seating. If that happens, the split ring cannot seat in its groove. It is easy for the assembler to knock a needle loose and it cannot be seen. The needles are held in place during assembly by the grease that lubes the bearing.

While assembling these is a simple process, it must be done correctly or the snap ring is thrown out and the bearing cup follows.