mvweebles

Guru

- Joined

- Mar 21, 2019

- Messages

- 7,218

- Location

- United States

- Vessel Name

- Weebles

- Vessel Make

- 1970 Willard 36 Trawler

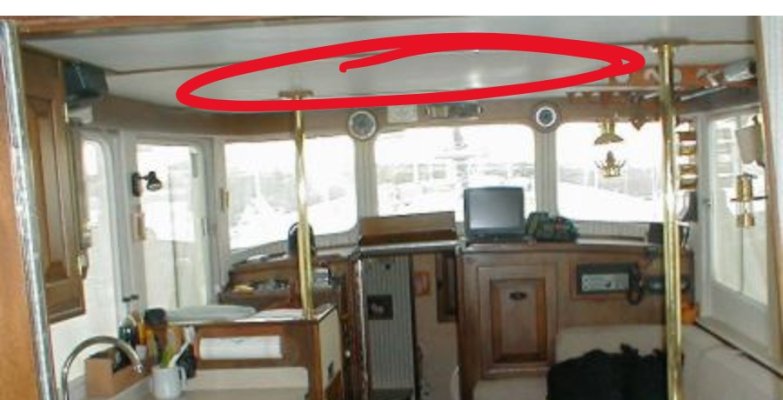

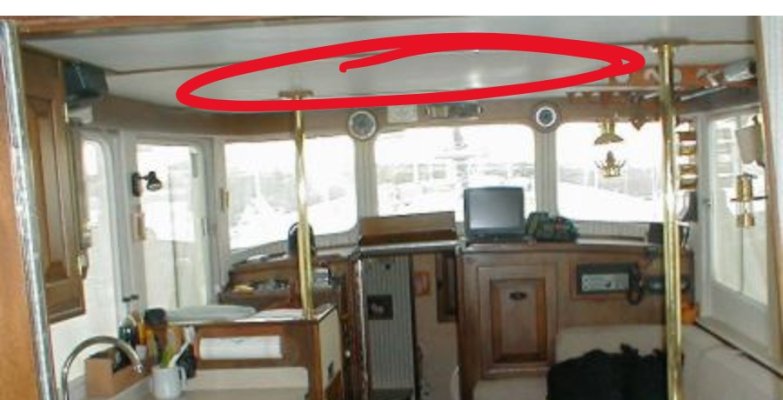

I'm adding 16k Btu Reverse Cycle A/C to my Willard 36 sedan. Would be super convenient to place it right over the salon in a semi-dead space of the flybridge bonnet.

Has anyone done this? probably 9-foot lift from waterline. I see many larger pumps have a 20+ foot head rating, but wondering if this is practical?

Second question - adding e a smaller 6k Btu Reverse Cycle to the forward stateroom. Compressor unit would be about 3-feet above waterline. Given the difference in head/height and the difference in size, could I run both off the same water pump with an appropriate 2:1 switch panel?

Thanks in advance.

Peter

Has anyone done this? probably 9-foot lift from waterline. I see many larger pumps have a 20+ foot head rating, but wondering if this is practical?

Second question - adding e a smaller 6k Btu Reverse Cycle to the forward stateroom. Compressor unit would be about 3-feet above waterline. Given the difference in head/height and the difference in size, could I run both off the same water pump with an appropriate 2:1 switch panel?

Thanks in advance.

Peter