Just when you think you have a problem sorted......

Because TF is often used as a research source for issues relating to older trawlers, in this case older marine engines, I thought it might be useful to continue with further developments in the rising engine temp saga.

As mentioned above, the IR temp gun indicated similar engine temps during a quick sea trial, although the gauges didn’t agree.

A check with the multi-meter measured 13.9 volts at the alternators, reducing to 13 at the helm panel, then 12.2 at the gauges themselves.

It appeared resistance in the electrical system was the gauge fault, a clean up of corroded pin connections, the worst were closest to alternators themselves being in the engine room, which improved the readings in volt and temp gauges.

At this stage I thought I was onto the problem, so did another sea trial a bit further, stb engine on the IR temp gun was more than 10 deg. C hotter than port?

This is the where you need to think back to everything you have recently done to the engines since they were running at normal temps.

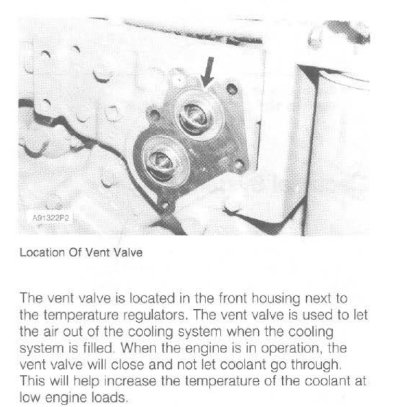

During a recent major service, both heat exchangers were removed the stripped for an acid dip/descale, where forum advice was to change the water regulators/thermostats while the 88 lb. (40 Kg) HE’s are off the engines.

Port side was done the previous year according to records, so I ordered two new ones from Cat for the stb engine.

According to Cat (which I’ve recently found out about but didn’t know about at the time) they recommend a 97 deg. C (206 deg F) water regulator for my 3208 NA, so this is what I installed alongside the 82 deg. C (180 deg. F) on the port engine.

I’m going to change the hotter temp water regulators for the 180 F versions, a total PITA because of the monstrous weight in a tight space, but prefer to have the gauge readings similar, and in case of a genuine overheat, more warning time, also not sure about the factory temp alarm sensors and how they will cope with the higher temp.

Also mentioned previously, the original cast iron, wet exhaust risers were replaced for custom SS dry risers (Greenwater Marine Exhausts) so a lot of overheat focus has been on the new retro fitted raw water plumbing, which besides the coolant air-lock scenario was high on the list of suspects. So far though the plumbing seems fine with good raw water flows.