BrianG

Senior Member

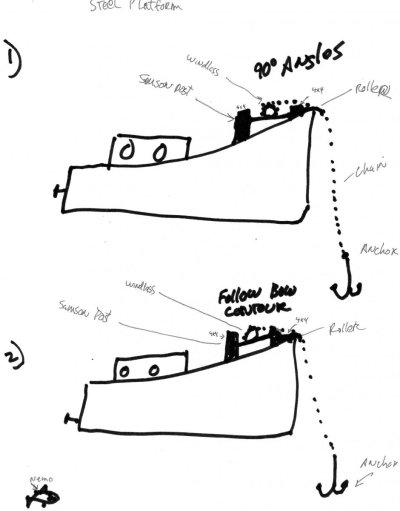

Question: I can make the platform 90 degrees to the Samson Post and bow 4x4 or, follow the graceful contour of the bow and deck and slope the stainless platform. The latter seems potentially more aesthetic the former possibly stronger? Advice sought. Thanks in advance. ps please don't make fun of my artistic "masterpiece".

Attachments

Last edited: