stevemitchell

Guru

- Joined

- Sep 25, 2018

- Messages

- 542

- Location

- USA

- Vessel Name

- Aruna

- Vessel Make

- Kristen Yachts 50 Pilot House

I'm posting this for a friend who lives aboard, and whose entire cruising season is over unless we can find the part.

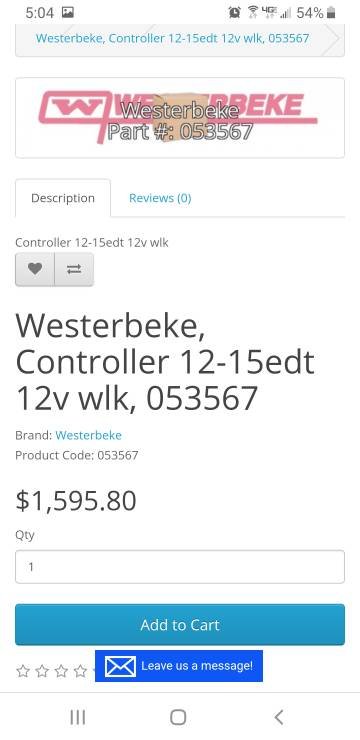

The Westerbeke part number is 053567 and it is the computer board for a 12.5 kw EDT generator. https://www.westerbeke.com/Product/CONTROLLER1215EDT12VWLK/053567

It was damaged by a leaking salt water pipe, and needs to be replaced.

Westerbeke, through the local service folks, have said none are in stock, and they have no ETA - maybe months or longer - due to supply issues. I'm sure this is related to COVID.

We're hoping we can find one somewhere, even a used one, or one sitting on a shelf at a distributor, even in a foreign country. It has to be programmed with the specific unit info, but Westerbeke seems like they could do that rather quickly.

If you have any ideas or leads on where to find Westerbeke parts, please let me know. A fellow trawlerite would be in your debt!

The Westerbeke part number is 053567 and it is the computer board for a 12.5 kw EDT generator. https://www.westerbeke.com/Product/CONTROLLER1215EDT12VWLK/053567

It was damaged by a leaking salt water pipe, and needs to be replaced.

Westerbeke, through the local service folks, have said none are in stock, and they have no ETA - maybe months or longer - due to supply issues. I'm sure this is related to COVID.

We're hoping we can find one somewhere, even a used one, or one sitting on a shelf at a distributor, even in a foreign country. It has to be programmed with the specific unit info, but Westerbeke seems like they could do that rather quickly.

If you have any ideas or leads on where to find Westerbeke parts, please let me know. A fellow trawlerite would be in your debt!