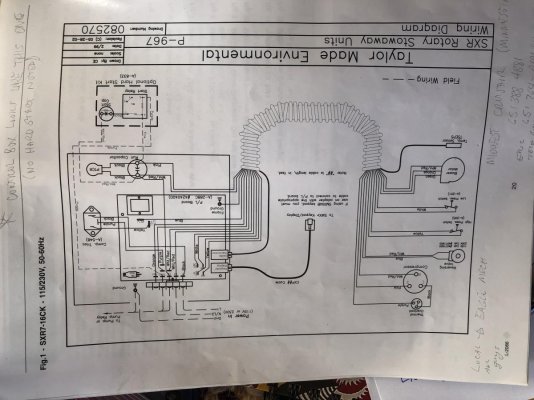

Smelled burning wire insulation then the breaker popped. 16 ton stowaway unit.

Inspection of control/ logic board showed black and purple wires on the TRIAC switch fried and oil leaking from the start/run capacitor. Fabricated new TRIAC wires and reconnected the circuit board. The control panel and fan work fine. Compressor and cooling pumps won’ start, although there is a “click” near the compressor when the cool button is selected. A second click occurs a second later.

Meter checks this morning show power to the black and yellow TRIAC wires at all times (cool button on or off). Nothing on the purple TRIAC wire. No evidence of power transfer to the cooling pump wires. (The shared pump works fine on the second AC unit.

I’m planning to purchase another TRIAC switch, a start/run capacitor and a PTCR. Any other suggestions? Can I bypass the logic board and jump start the compressor to eliminate it as a failure? Other than these things am I facing the dreaded logic/control board replacement? Is there a place that refurbishes them? I’m not capable of trouble shooting a circuit board.

All ideas much appreciated. Thanks

Inspection of control/ logic board showed black and purple wires on the TRIAC switch fried and oil leaking from the start/run capacitor. Fabricated new TRIAC wires and reconnected the circuit board. The control panel and fan work fine. Compressor and cooling pumps won’ start, although there is a “click” near the compressor when the cool button is selected. A second click occurs a second later.

Meter checks this morning show power to the black and yellow TRIAC wires at all times (cool button on or off). Nothing on the purple TRIAC wire. No evidence of power transfer to the cooling pump wires. (The shared pump works fine on the second AC unit.

I’m planning to purchase another TRIAC switch, a start/run capacitor and a PTCR. Any other suggestions? Can I bypass the logic board and jump start the compressor to eliminate it as a failure? Other than these things am I facing the dreaded logic/control board replacement? Is there a place that refurbishes them? I’m not capable of trouble shooting a circuit board.

All ideas much appreciated. Thanks

Last edited: