balder8

Senior Member

- Joined

- Aug 15, 2018

- Messages

- 103

- Location

- France

- Vessel Name

- BALDER VIII

- Vessel Make

- North Sea Trawler 57' OC

Hi!

Bonjour à tous,

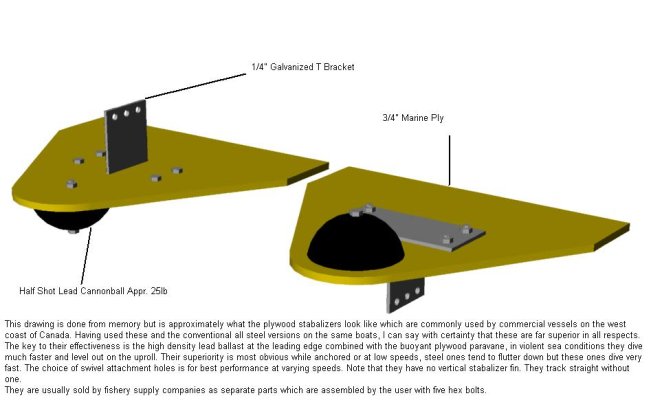

First of all, thanks to all boaters and trawler owners who are posting pics, drawings, comments and explanations concerning this very crucial subject on passagemaker trawlers: the paravane design as unique system for stbailization underway or as a back up for long range cruising.

I think trawlerforum is certainly the only one forum where you can find this level of quality! With a very friendly atmosphere!

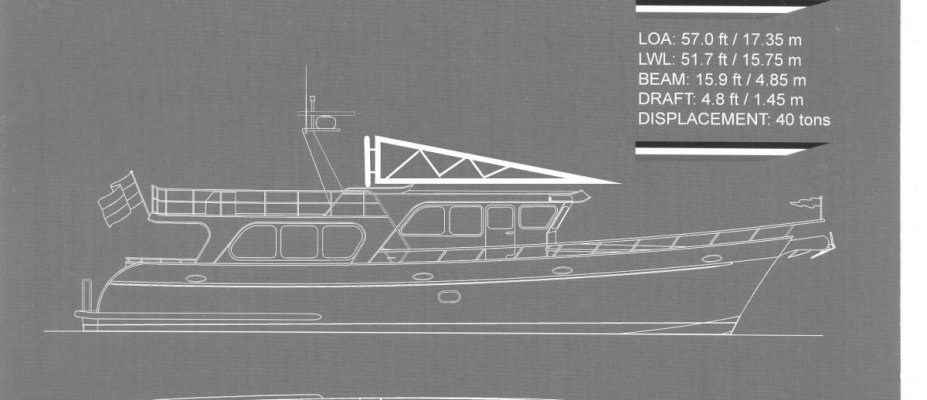

So, I have decided to go with paravanes as a back up ( I have Keypower stabs installed) for my next ocean crossing aboard Balder VIII, north sea trawler 57' built by excellent Dutch boat yard Tinnemans'BV.

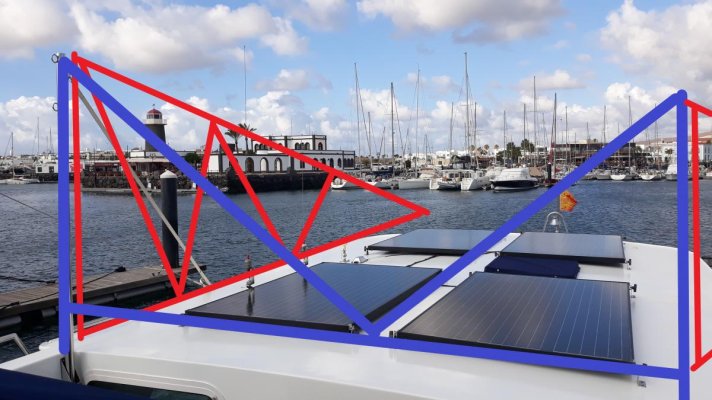

Instead of considering an extra A frame design with mast etc, as used on Nordhavn, KageyKrogen and described in the fantastic book " Voyaging under power", I am planning to retrofit a stainless steel rigid structure based on an horizontal solid foldaway arms/stabilizer design as shown below on the picture of the australian fishing boat shown on M/V Dirona blog ( thanks to them!)

On my plan, paravanes are 20' long. An engineer is calculating the diameter and sizes of all this rig, may be in stain less steel.

Here some pictures of my project.

Is it necessar to say that all comments or advices will be welcome and appreciated???

Kind regards

Dominique

Bonjour à tous,

First of all, thanks to all boaters and trawler owners who are posting pics, drawings, comments and explanations concerning this very crucial subject on passagemaker trawlers: the paravane design as unique system for stbailization underway or as a back up for long range cruising.

I think trawlerforum is certainly the only one forum where you can find this level of quality! With a very friendly atmosphere!

So, I have decided to go with paravanes as a back up ( I have Keypower stabs installed) for my next ocean crossing aboard Balder VIII, north sea trawler 57' built by excellent Dutch boat yard Tinnemans'BV.

Instead of considering an extra A frame design with mast etc, as used on Nordhavn, KageyKrogen and described in the fantastic book " Voyaging under power", I am planning to retrofit a stainless steel rigid structure based on an horizontal solid foldaway arms/stabilizer design as shown below on the picture of the australian fishing boat shown on M/V Dirona blog ( thanks to them!)

On my plan, paravanes are 20' long. An engineer is calculating the diameter and sizes of all this rig, may be in stain less steel.

Here some pictures of my project.

Is it necessar to say that all comments or advices will be welcome and appreciated???

Kind regards

Dominique

Attachments

-

Projet Paravane horizontal et bidirectional DEC 3.jpg72.8 KB · Views: 110

Projet Paravane horizontal et bidirectional DEC 3.jpg72.8 KB · Views: 110 -

Schema paravane horizontaux balder 8.pdf371.2 KB · Views: 39

-

Project PARAVANE vue de dessus avec renfort transversal.jpg121.3 KB · Views: 112

Project PARAVANE vue de dessus avec renfort transversal.jpg121.3 KB · Views: 112 -

paravane horizontale.jpg91.2 KB · Views: 145

paravane horizontale.jpg91.2 KB · Views: 145 -

projet PARAVANE horizontal et bidirectional DEC .jpg121.2 KB · Views: 113

projet PARAVANE horizontal et bidirectional DEC .jpg121.2 KB · Views: 113