So, take a look at this page:

--

https://www.littelfuse.com/products...ent-relays/continuous-duty-spst/24059-08.aspx

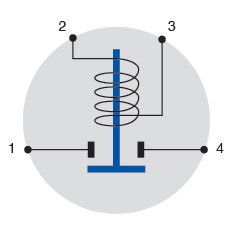

And, you'll find the attached picture.

Let's imagine that your battery+ is attached to terminal #1 and your windlass+ is attached to terminal #4. We see that the windlass is not normally powered, because the switch is normally "open". For example, a spring may hold it in the "up" position shown in the picture.

Now, if we look at terminals #2 and #3 we see that they are two the two different sides of a coil -- an electromagnet. When that coil is energized, the electromagnet pushes the switch connection downward, connecting terminals #1 and #4. As long as that coil stays powered, the electromagnet is energized and the switch bar is pushed closed, supplying power to the windlass.

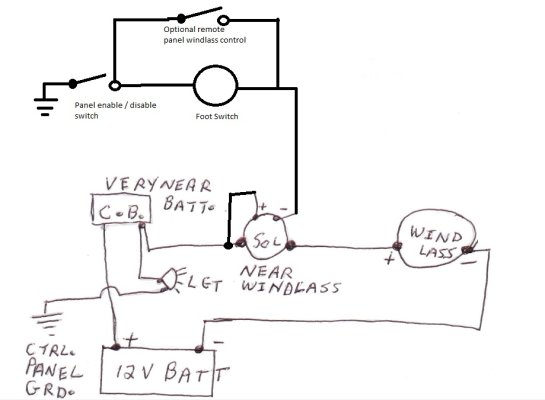

For this to work, we need to have +12V going into one end of the coil, and the other end of the coil connecting back to the 12v ground. So, the way this usually works is that +12V is supplied to one side of the coil, say terminal #2, and one wire of the foot switch is attached to the other side of the coil, say terminal #3. The other wire of the foot switch goes back to the 12 ground.

The foot switch is "normally open", meaning that it is an open connection until you step on it. So, while you aren't stepping on the foot switch, the coil isn't energized, and the switch controlling the windlass is open -- the windlass is off.

But, when you step on the foot switch, you close the switch, completing the circuit, allowing current to flow through the coil, energizing the electromagnet, and closing the switch that controls the windlass -- so the windlass is on as long as you are stepping on the foot switch and off otherwise.

This is done because it takes a relatively small amount of current to drive the electromagnet as compared to the windlass. This enables small wiring, etc, to the foot switch.

In /general/ 4-post (4 terminal) solenoids need a +12V supplied to each the coil and the load. In /general/ 3-post solenoids have a single +12V post (terminal) and split it internally so that it goes to each of the switch for the load and the input side of the coil.

Since you drew your solenoid with 4 posts (terminals), which is consistent with the figure for the terminal you showed, I think you need to supply +12V to each of the input side of the coil and to the input side of the load switch, even if by jumpering from one to the other.