AKDoug

Guru

Hello all,

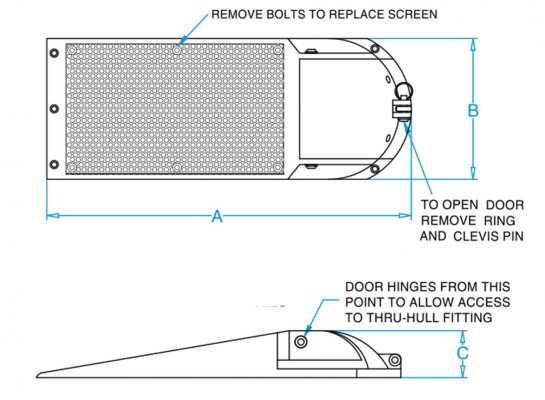

I am not finding a previous thread covering this when I search, so looking for someone who has done it. I am installing a Spectra water maker, and the manufacturer calls for a scoop (facing forward) thru hull for the unit. I have installed many mushroom thru hulls, but wondered about the four screws that mount the strainer to the hull.

Do they go all the way through the hull, part way into the hull, or what? Also, I am assuming they are stainless screws as I find no bronze screws available anywhere in an appropriate size. I am also assuming removing bottom paint to gel coat under the scoop, and generous 4200 or 5200 as in my previous installs.

Looking for the poop from someone who has done it!

Thanks

I am not finding a previous thread covering this when I search, so looking for someone who has done it. I am installing a Spectra water maker, and the manufacturer calls for a scoop (facing forward) thru hull for the unit. I have installed many mushroom thru hulls, but wondered about the four screws that mount the strainer to the hull.

Do they go all the way through the hull, part way into the hull, or what? Also, I am assuming they are stainless screws as I find no bronze screws available anywhere in an appropriate size. I am also assuming removing bottom paint to gel coat under the scoop, and generous 4200 or 5200 as in my previous installs.

Looking for the poop from someone who has done it!

Thanks