sbman

Guru

- Joined

- Jul 25, 2017

- Messages

- 828

- Location

- USA

- Vessel Name

- Second Chance

- Vessel Make

- 42' Uniflite Double Cabin

The Uniflite isn't a trawler, but I thought some might be interested in what goes into refitting an older fiberglass boat purchased at a low price, of course it costs more than you think it will, by quite a bit.

This particular Uniflite is a 1977 model with dual Detroit 671N engines, a double cabin layout with two heads, one shower, a dinette and down galley.

Prior to my ownership, the boat had been a live aboard at a mooring in San Diego for about 15 years. Two owners before me had not operated the boat much in that time.

A new owner bought the boat sometime in 2016 with the thought of fixing it up, and spent quite a bit of money getting the starboard engine sorted out, as the previous owner had used it regularly. However, the Port engine was rusted up and had been neglected from non-use and was locked up, needing an overhaul.

He managed to tear the starboard shaft log tube (I think they were original tubes) and the boat was slowly leaking water continuously through this torn shaft log. With temporary repairs in place, the boat needed to be hauled out for both the shaft log issue as well as port engine repairs among other system upgrades and repairs. I purchased the boat at a very low price and scheduled a haul out as well as transportation to a working yard where I'd be able to do most of the work myself.

The list of work to be completed while out of the water includes:

This particular Uniflite is a 1977 model with dual Detroit 671N engines, a double cabin layout with two heads, one shower, a dinette and down galley.

Prior to my ownership, the boat had been a live aboard at a mooring in San Diego for about 15 years. Two owners before me had not operated the boat much in that time.

A new owner bought the boat sometime in 2016 with the thought of fixing it up, and spent quite a bit of money getting the starboard engine sorted out, as the previous owner had used it regularly. However, the Port engine was rusted up and had been neglected from non-use and was locked up, needing an overhaul.

He managed to tear the starboard shaft log tube (I think they were original tubes) and the boat was slowly leaking water continuously through this torn shaft log. With temporary repairs in place, the boat needed to be hauled out for both the shaft log issue as well as port engine repairs among other system upgrades and repairs. I purchased the boat at a very low price and scheduled a haul out as well as transportation to a working yard where I'd be able to do most of the work myself.

The list of work to be completed while out of the water includes:

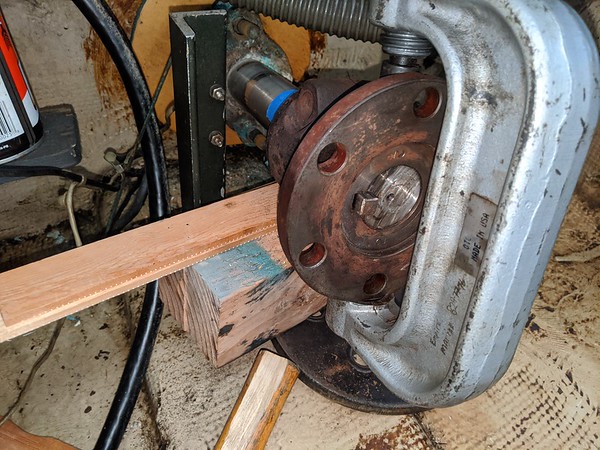

- Shaft log tube replacement, both sides

- Stuffing box cleaning and repacking, both sides

- Port engine rebuild

- Onan generator removal (it is non functional)

- Cutlass Bearing replacement, both sides

- Prop replacement

- Below waterline blister repair, epoxy barrier coating

- Steering system overhaul (rebuild pumps, put new fluid)

- Add inspection ports to fuel tanks and clean out

- Paint hull above waterline

- Misc Electrical repairs

- Service and/or replacement of all thru hulls

- Bilge cleaning