- Joined

- Nov 8, 2012

- Messages

- 2,315

- Location

- USA

- Vessel Name

- Sandpiper

- Vessel Make

- Bluewater 40 Pilothouse Trawler

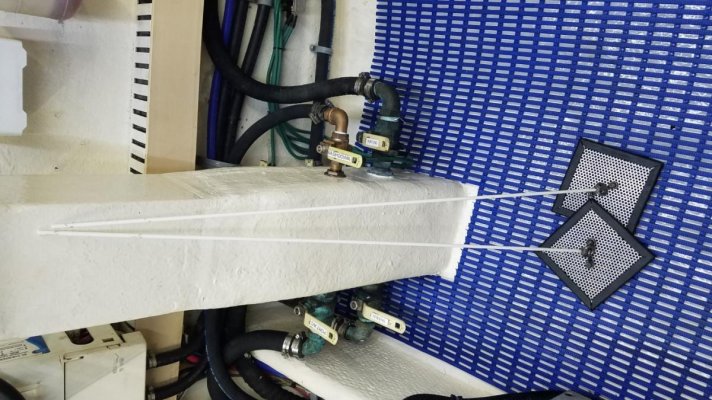

My Perkins in a 34 Mainship always needed a priming after splash. I needed to close the sea cock. Open the strainer and fill the strainer with water. Simply opening the sea cock was not effective. I’m assuming there was an airlock in the engine hose and by opening the strainer enough air was “burped” out of the engine hose to allow the water pump to pull salt water. In my case it was a 1 1/2” hose about 4’ long.

I experienced a similar fate on my FL after impeller change. Filling the strainer did not burp the air between strainer and pump. Had to disconnect hose from the strainer and fill it with water.

I caught it within seconds of starting so no damage to the impeller. I grease up the impeller and the inside of the pump when replacing impellers.

I recently started using Globe Run-Dry impellers in the generator. They are guaranteed to run 15 minutes without water. As soon as I use up my stock of engine impellers, I will switch to Globe.

I replace impellers every two years.