I'm in the process of building my second Olympia-based, real heater-base system, and can share what I'm doing differently. The changes aren't necessarily because there was a problem with the first system, but I can't help myself trying to make improvements. I'll mention where I think there is something that will really matter to you, but otherwise just take it for general consideration and entertainment.

- I agree with Sunchaser that measuring loop temp, especially in multiple places, is really more of a design verification exercise rather than on going monitoring. So I definitely wouldn't install multiple sensors. However I do plan to install one on the supply side manifold. I don't think there is huge value in it, but I plan to anyway. I'm also curious to see how the loop temp holds up when running off engine heat, but that is arguably a one-time design verification check.

- I will install a pressure sensor, and recommend it, mostly to monitor for leaks. Even if the system has a shut down, which I agree it should, I want to know when a leak is happening, not after it has happened. I agree that leaks can and probably will develop at times over the life of the system, but those are faults that should be corrected. A properly operating system should lose no fluid. None, zip, zilch, nada. If it is losing some, I want to know right away.

- Setting up to run off waste engine heat while underway is a wonderful thing, so I highly recommend it if at all practical.

- My last system has no automatic zone valves, so hot water circulated through all the loops whenever the circulator was running. There were manual valves so I could shut off everything except the HW in the summer, but it was manual. Up to a point I think this approach is fine, but on the new system I am building it the way a home system is done with automatic zone valves that are responsive to the thermostats. This better directs the heat where you want it, when you want it. It may be overkill, but I did it anyway. But this was prompted by a particular issue, so read on....

- I encountered an interesting phenomenon on my last system, and it's what prompted me to use zone valves on the new system. One loop ran through the HW tank to head domestic hot water from the boiler. That was all good. However when at dock and on shore power, I used the electric HW heat. Now if the heat demand from the living space was light, the boiler would cool down between runs, and when it would start up, the water flowing through the HW heater would actually draw heat out of the HW tank rather than put heat in. The electric HW would kick on, and I was effectively heating the boat with electric, at least to some degree. So at a minimum I wanted a zone valve to only direct water through the HW tank when there was actually a call for heat from it. This whole thing wasn't the end of the world, but I decided to improve on it in the next system.

- I am planning on monitoring the burner on/off time in one way or another. They may have changed it, but on the last SureWire control box the hour meter ran whenever there was power to the system, not burner run time. So it measured breaker-on time, which was always, and totally useless. This time I want a meter that counts burner run time. That's what drives maintenance, so that's what I want to monitor. Now the new SureWire box is quite different, and I don't know yet whether the hour meter function has changed, but I'm not using the SureWire box, so haven't pursued it. A call to them would probably answer the question. I plan to either install an hour meter, or monitor and count run time with Maretron.

- On a refit it might not be an option, but I have insulated my PEX heating loops. And many people prefer not to insulate them because they indirectly bring heat to other parts of the boat. A friend is building an identical boat to mine (as much as any two Nordhavn's are the same - not) and he has elected not to insulate. So people go both ways.

- Many boats, like my last one, are built with a header tank to maintain water pressure. This time around I am building a closed system with an expansion tank, as you would build a home system. This eliminates the need for a tank at the highest point in the system, and gives a little more control over pressure.

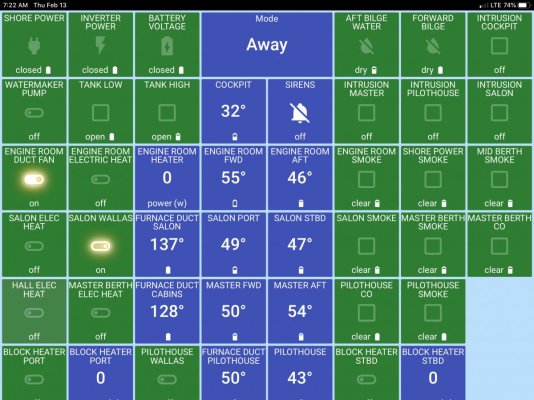

- For monitoring, I think room temp is the most important thing to monitor. That will tell you whether the heat is working, or if you have a problem that needs to be tended to right away. I left our heat on all the time, just as I do at home. When we were away from the boat I just turned the temp down. That protected against freezing, and left a more approachable boat when we returned.