Island Cessna

Senior Member

- Joined

- Feb 19, 2011

- Messages

- 307

The photos, I hope:

Peter’s drawing with my configuration added.

As you can see the gooseneck gets the exhaust run up high enough that a check valve is not required.View attachment 99033

The gooseneck protruding above the sole, and blocking the stbd half of the double door.

View attachment 99034

Thanks Bill - Looks like the type of modification that has a back-story to it. What engine does your W36 have? I didn't quite follow where your exhaust outlet through the hull is and how high off the waterline.

Interesting. My 1970 W36 has a 1989 4.236 so something changed on my boat too. Most W36s had 6.354s in them, though there is a smattering of other engines including GMs and old Gray Marines (a GM variant). In my opinion, the 80hp 4.236 is perfectly matched to W36, though my preference would be a JD 4045NA, but not enough of a preference to repower.The engine is a Perkins 4-236. It was installed new in the late ‘90’s, and is equipped with a full set of Murphy Switchgauges, so I’d do suspect there is at least one back-story, but I have not heard it! Location of exhaust outlet and waterline in photo. I do not se any evidence of a past outlet on the stern centerline like most W36S have, so I assume this is the original location. BillView attachment 99039

On boats with low exhaust outlets, I've installed the Vetus gooseneck with great results.

I've mixed Vetus Goosenecks with Centek mufflers and Gen Seps or used the Vetus mufflers.

This is the perfect setup for the W36S. The gooseneck will fit perfectly in the tiller compartment under the cockpit seat!

I looked at these - there is indeed a very good place to install one on a Willard 36 that would get the exhaust well above the waterline (and the cabin sole). But it would only be a high-point just inside the hull. Obviously, it would keep water out, but would also keep water in. On the engine-side of this high-point is 8-10 feet of 3"D hose plus the muffler lift muffler. I'm struggling to understand how that's a good thing. It's an honest question - I just don't understand. Maybe it's only a problem if the engine is over-cranked and I shouldn't worry. But it just seems like having so much of the exhaust system where water can collect just doesn't seem like a good idea. What am I missing?

Peter

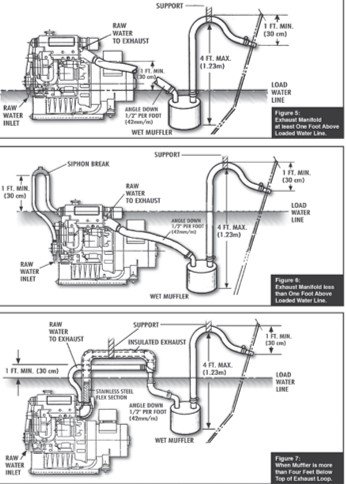

I haven't read everything, but this makes sense to me. I noticed in one of the diagrams that the lift muffler is actually raises up so that waterline is roughly midway up the muffler.https://www.sbmar.com/category/articles/exhaust-systems/

I have shown above a link to Tony Athens' articles about marine exhaust systems. This is just the start. Take a serious look at his articles and examples.

He is strongly of the opinion that the highest point in the system should be immediately AFTER the turbo, NOT after the waterlift muffler. The cooling exhaust shower head should be just after the highest point downturn so even should that shower head leak the water cannot go back to the engine.

THis setup will not allow the engine to be flooded even if the waterlift is filled.

I strongly suggest you Read his articles, study them.

Brooksie - I don't disagree, I'm just confused. There's a piece of me that says that if the second loop (after the muffler) is lower than the exhaust/mixing loop, there is no way it can back up onto the engine anyway. Not sure that's possible on the W36.There is no requirement that, after leaving the waterlift that the hose travels downhill at all (mine is nearly level under the sole then turns up & down 12" at the transom in a gooseneck)

The purpose of the gooseneck is to prevent dipping up water in the outlet while hobby horsing at anchor, rolling it down the hose, filling the waterlift and eventually the engine. Flaps and check valves are not reliable enough to prevent this long term.

As long at the waterlift is large enough to hold any water that may be in the hose when the engine is shut down, it need not run out the outlet.

Sorry to chime in again on this but I have put a trouble free system in the exact same vessel...

Brooksie - I don't disagree, I'm just confused. There's a piece of me that says that if the second loop (after the muffler) is lower than the exhaust/mixing loop, there is no way it can back up onto the engine anyway. Not sure that's possible on the W36.

I'll get some measurements on the boat (will ping the Willard owners to see if anyone is on/near their boat as I'm 3000 miles away from mine). I'd like to ping the Tony guy cited by a previous post. Seems pretty sharp too. And get a feel for ABYC. Both he and Steve D cite those standards. Finally, have to figure out what physical constraints there are such as very low deck.

Thanks all - though in still confused, has been helpful.

Peter

https://www.sbmar.com/category/articles/exhaust-systems/

I have shown above a link to Tony Athens' articles about marine exhaust systems. This is just the start. Take a serious look at his articles and examples.

He is strongly of the opinion that the highest point in the system should be immediately AFTER the turbo, NOT after the waterlift muffler. The cooling exhaust shower head should be just after the highest point downturn so even should that shower head leak the water cannot go back to the engine.

THis setup will not allow the engine to be flooded even if the waterlift is filled.

I strongly suggest you Read his articles, study them.

I was at the Vancouver Boat Show yesterday and saw one of these: https://www.vetus.com/en/exhaust-systems/waterlock-muffler.html .

Certainly a way to put a high loop in the tiller compartment to avoid sloshing back from discharge without worrying whether the water lift could hold any drain-back from the long horizontal run of hose under cockpit deck. Bill