sbman

Guru

- Joined

- Jul 25, 2017

- Messages

- 828

- Location

- USA

- Vessel Name

- Second Chance

- Vessel Make

- 42' Uniflite Double Cabin

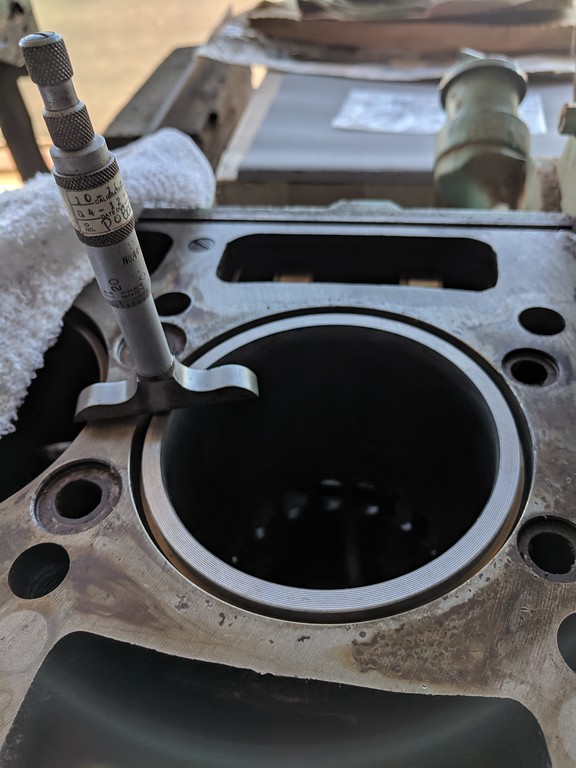

Nice. Always liked that "cross-head" piston design.

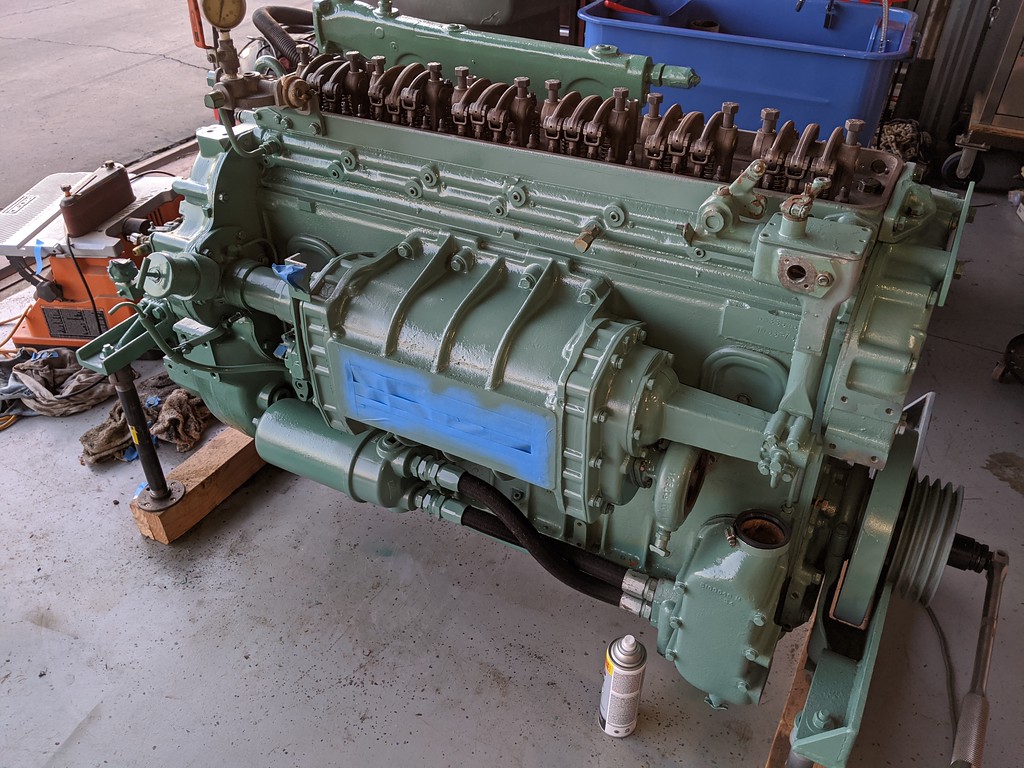

Note the six cyl two stroke has an inherent imbalance, so getting all the masses exactly the same is not real important. Not the same as a six cyl four stroke. That's the reason for the eccentric weights on each end of the cam and balance shafts. They "mostly" cancel the first order vibe, but engine still has a wiggle.

Understood, that's why I didn't go to the lengths I would go to on most engines. I figured I'd at least match up the components to get the weights as close as I could and they ended up coming out really close.