Eric---

If I am interpreting your comments about twin-engine vs. single-engine maintenance costs correctly, many twin engine boats use exactly the same engine as the single engine version of the same boat. For example, you could get the GB36 in twin or single. In the 1960s and 70s, the engine used most often in either version was the Ford Lehman 120. The only difference was how many FL120s you had.* For*a newer example, in the 1990s the GB36 could be had with one or two Cummins 210 hp engines. Again, the exact same engine in the single or twin GB36. So if it takes $800 dollars to service one Cummins 210, it will take $1,600 to service two of them.

It may be that there were-- or are-- production boats out there that in the single-engine version use a larger engine than the same boat would have in the twin-engine version. But with GB, at any rate, the models that were available in both single and twin engine configurations almost always used the same horsepower engines in the twin that were used in the single engine version. And I think the same held true for boats like CHBs, etc.

Also, I've not found that a small oil filter or smaller belt costs always costs less. In my experience, the same type of filter costs pretty much the same regardless of size. Same with belts unless there is a signficant size difference. Anyway, many larger engines use the same size filters and belts as smaller engines, so I don't think this cost is really going to be affected by the power of the engine.

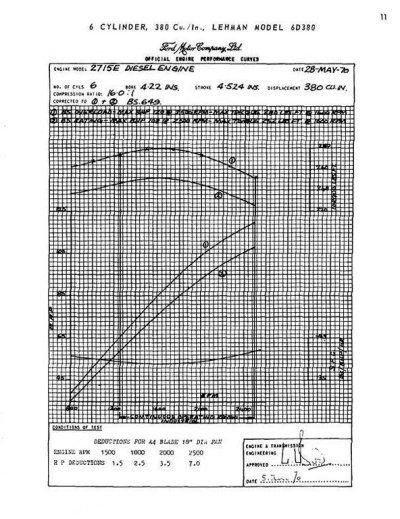

The notion that a higher powered engine will automatically be more expensive to maintain than a lower power engine is not always the case. Take Carey's lobsterboat and our boat. Carey has a 425 hp Cat. We have two 120 hp Lehmans. But even if we had only one Lehman, Carey's maintance costs would still be way lower than ours if for no other reason than his engine has much longer service intervals than our engine. And servicing is much easier and faster on Carey's engine, so if the work is done professionally, the labor cost to service his engine will be considerably lower than the labor cost to service one of our engines.

So I don't think you can really tie maintenance costs to the power of an engine. The costs will depend on the engine's technology and its ease of accessibility in the boat-. In other words, things that affect how often it has to be maintained or serviced, and how much that service will cost in terms of materials (oil, belts, filters, etc), and labor time.

Where I do think your basic comparison cost is correct is in the fuel burn of a single vs. a twin. I don't believe that a GB36 with two FL120s will burn twice the fuel in cruise as a GB36 with one FL120. I'm not sure the twin will burn 120 percent of the fuel the single will burn--- it might be more like 150 percent--- but given the same kind of boat, same speed, same weight, etc., the twin's fuel consumption will not be double.

Also, I agree that the total volume of space inside a long, narrow boat can be the same as the space in a shorter, wider boat. What I meant in my earlier comment is that it seems a lot of modern "fat" boats use their width for house-like amenities like big tables, transverse settees, big, L-shaped galleys, and so on. This kind of interior layout would have to change if boats went back to being narrow, and some people might be reluctant to give up their big, wide "living rooms"

Interestingly enough, the almost flat afterbody of a GB's semi-planing hull does slope up toward the stern until at the transom the bottom of our boat is only a couple of inches below the surface at it's outboard edges and not much more in the middle. I assume this adds to its efficiency as well as the ability to be driven faster without a ridiculous amount of extra power. Even with our two FL120s, we can get about 11 or 12 knots at full throttle out of the boat (which has a theoretical hull speed of about 8 knots) but we need to run an extension hose to the marina's fuel dock in order to do it

-- Edited by Marin at 15:30, 2008-02-04