angus99

Guru

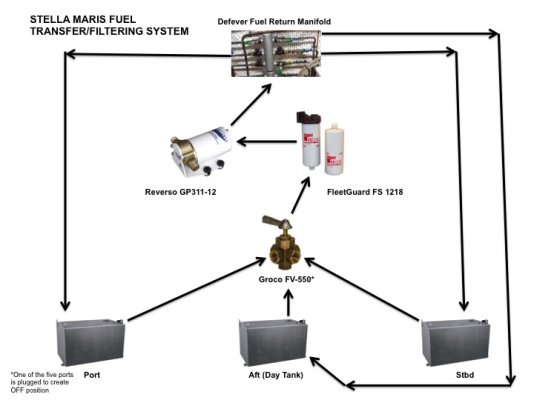

Got things hooked up yesterday for a test run and it all works perfectly.  I replaced a jury-rigged collection of pipes and antiquated equipment with a new Fleetguard, Reverso pump, multi-port selector valve and hoses. With this system, I can transfer filtered fuel to the day tank before each day’s run . . . a 20-minute job while getting ready to get underway. (The Reverso on the right in the second photo is our oil change pump.)

I replaced a jury-rigged collection of pipes and antiquated equipment with a new Fleetguard, Reverso pump, multi-port selector valve and hoses. With this system, I can transfer filtered fuel to the day tank before each day’s run . . . a 20-minute job while getting ready to get underway. (The Reverso on the right in the second photo is our oil change pump.)

I want to replace two valves (one at the bottom of each saddle tank) that feed the transfer/filtering system because one or both leaks through when closed. And they are a bear to get at. The leak through is actually a tiny stream when both valves are closed and one of the fittings downstream is removed. (The gravity transfer hose between tanks was connected at the time I was discovering this, so I couldn’t tell for sure which valve leaks (maybe both?).

The second last photo shows one of the valves on a nipple coming from the stbd tank. A hose barb goes on the capped Tee and routes fuel to the new transfer pump and filter. The open flare fitting at the bottom is for the gravity transfer hose the P/O used for boat trim. I was thinking of removing this fitting and adding a simple drain valve and plug to quickly test for water and sludge. (We never use the gravity transfer hose—we keep the boat trimmed using the transfer pump and alternating supply tanks as needed.)

I tried to get the valve pictured off yesterday using a pipe wrench and vice grips twisting in opposite directions, but it’s really hard to get at and I couldn’t apply full force. Thought I’d try again with two pipe wrenches and pieces of pipe over the handles to increase torque but I’m a little worried about spinning the nipple where it connects to the tank. If it’s threaded (as it seems to be in the last photo) it would be no problem to reinstall. But if it’s welded or rusted to the tank and I twist I it off, I’m screwed . . . boned . . . F‘d . . . even though both saddle tanks are currently empty.

Would appreciate any thoughts on removing these valves (not sure I should apply heat around diesel tanks— even if mostly empty). Also, any reason to keep the gravity transfer hose?

As always, thanks for all ideas.

I replaced a jury-rigged collection of pipes and antiquated equipment with a new Fleetguard, Reverso pump, multi-port selector valve and hoses. With this system, I can transfer filtered fuel to the day tank before each day’s run . . . a 20-minute job while getting ready to get underway. (The Reverso on the right in the second photo is our oil change pump.)

I replaced a jury-rigged collection of pipes and antiquated equipment with a new Fleetguard, Reverso pump, multi-port selector valve and hoses. With this system, I can transfer filtered fuel to the day tank before each day’s run . . . a 20-minute job while getting ready to get underway. (The Reverso on the right in the second photo is our oil change pump.)I want to replace two valves (one at the bottom of each saddle tank) that feed the transfer/filtering system because one or both leaks through when closed. And they are a bear to get at. The leak through is actually a tiny stream when both valves are closed and one of the fittings downstream is removed. (The gravity transfer hose between tanks was connected at the time I was discovering this, so I couldn’t tell for sure which valve leaks (maybe both?).

The second last photo shows one of the valves on a nipple coming from the stbd tank. A hose barb goes on the capped Tee and routes fuel to the new transfer pump and filter. The open flare fitting at the bottom is for the gravity transfer hose the P/O used for boat trim. I was thinking of removing this fitting and adding a simple drain valve and plug to quickly test for water and sludge. (We never use the gravity transfer hose—we keep the boat trimmed using the transfer pump and alternating supply tanks as needed.)

I tried to get the valve pictured off yesterday using a pipe wrench and vice grips twisting in opposite directions, but it’s really hard to get at and I couldn’t apply full force. Thought I’d try again with two pipe wrenches and pieces of pipe over the handles to increase torque but I’m a little worried about spinning the nipple where it connects to the tank. If it’s threaded (as it seems to be in the last photo) it would be no problem to reinstall. But if it’s welded or rusted to the tank and I twist I it off, I’m screwed . . . boned . . . F‘d . . . even though both saddle tanks are currently empty.

Would appreciate any thoughts on removing these valves (not sure I should apply heat around diesel tanks— even if mostly empty). Also, any reason to keep the gravity transfer hose?

As always, thanks for all ideas.

Attachments

-

FDA9C760-3B4C-4768-890E-6E281AD64056.jpeg60.8 KB · Views: 45

FDA9C760-3B4C-4768-890E-6E281AD64056.jpeg60.8 KB · Views: 45 -

C85BE369-D4DA-44E3-BECC-801CB7D4C250.jpg114.8 KB · Views: 40

C85BE369-D4DA-44E3-BECC-801CB7D4C250.jpg114.8 KB · Views: 40 -

0DF55645-99BB-491F-9027-FD5014CC240E.jpg107.2 KB · Views: 38

0DF55645-99BB-491F-9027-FD5014CC240E.jpg107.2 KB · Views: 38 -

AFB60E80-2D19-42BE-91CD-BCC255D78C48.jpg109.1 KB · Views: 36

AFB60E80-2D19-42BE-91CD-BCC255D78C48.jpg109.1 KB · Views: 36 -

845D76A5-A618-4F65-A8DD-A49ED80676F5.jpg104.2 KB · Views: 41

845D76A5-A618-4F65-A8DD-A49ED80676F5.jpg104.2 KB · Views: 41 -

99B28AFB-BD86-48FB-8A2E-062CAC1CEF35.jpg118.4 KB · Views: 42

99B28AFB-BD86-48FB-8A2E-062CAC1CEF35.jpg118.4 KB · Views: 42

Last edited: