SteveK

Guru

- Joined

- Jul 5, 2019

- Messages

- 5,074

- Location

- Gulf Isalnds BC canada

- Vessel Name

- Sea Sanctuary

- Vessel Make

- Bayliner 4588

Gkesden

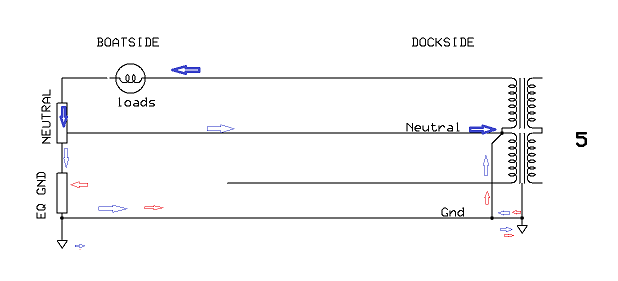

Thanks I have found the answer I was looking for. The inverter switches both hot a d neutral. Shore power passes through inverter. inverter alone supplies both a d bonds to ground without shore power. Brain fart solved

Thanks I have found the answer I was looking for. The inverter switches both hot a d neutral. Shore power passes through inverter. inverter alone supplies both a d bonds to ground without shore power. Brain fart solved