[SIZE=+1]Calculating the propeller parameters (Torque, efficiency, etc.) is actually very simple for standard props like yours. I used Oosurveld and van Oossanen (1975) (link -

https://pdfs.semanticscholar.org/33ef/fe719f9292950e7f89f1122695256f16a3fe.pdf ) to calculate the propeller thrust and torque coefficients, Kt and Kq, respectively for Wageningen B-Screw Series propellers. You will also need resistance calculations for the hull. I used the methods outlined in [/SIZE][SIZE=+1][SIZE=+1]

Larsson and Eliasson (1994) to calculate hull resistance.[/SIZE]You will need hull parameters to calculate the hull resistance which will require having the hull lines, but I assume you can take the lines from the hull if you can't find the designer to get them from. All very easy to do.[/SIZE]

[SIZE=+1]

[/SIZE]

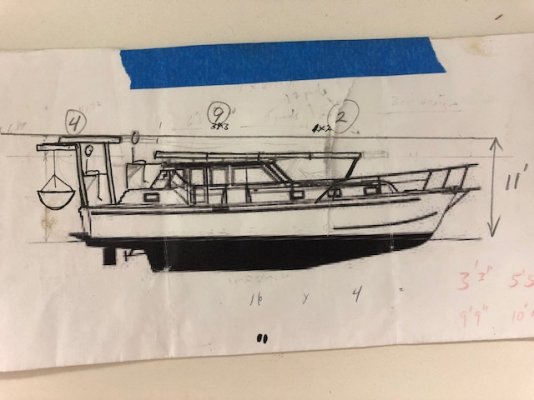

[SIZE=+1]Incidentally I considered going electric when I repowered my boat. My boat has a 32' waterline and the hull is a round chine full displacement hull which is very easy to drive. On flat water my boat requires about 5 kilowatts to maintain 6 knots. I have room for about a kilowatt of solar on my cabin top so it would take about two days to recover from 1 hour of cruising at 6 knots. At 4 knots my boat would take about 1.8 kilowatts so I could recover from an hour at four knots in a day most of the time. What decided me against going electric was the cost. I would need at least 20 kilowatts of batteries which was prohibitive cost wise back in 2010 when I was repowering. Even now usable 20 kilowatts of lithium iron phosphate batteries would cost me about $15,000, which is nearly twice what I paid for a new diesel. That cost doesn't include the electric motor, controller, battery charging capability, ancillary electrical components, mounting the motor and batteries or any of the costs for a solar array. My preliminary cost estimate back then was over $30K for a complete setup, which was cost prohibitive. Note that 20 kilowatts of battery power would give me a range of 44 nm at four knots and 24 nm at 6 knots. That would be adequate for a day cruiser that wasn't used every day, but would not be viable for multi day trips.

[/SIZE]

[SIZE=+1]

[/SIZE]