bridaus

Senior Member

How do you do it? Pictures especially welcome here.

My battery cables run along side the engine on top of a stringer (rail, can't recall the word) and the PO built a "box" around them complete with nails (ugh) to protect them.

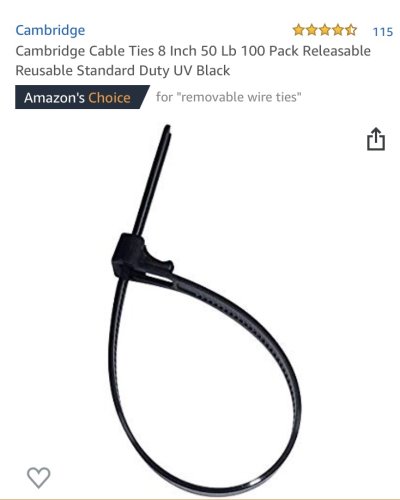

Some others appear to be screwed direct to fiberglass with twist tie like holders. Doesn't that compromise the inner hull moisture-wise?

Others are just lying around. More ugh.

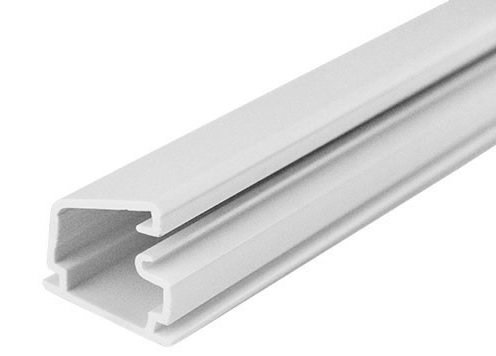

I'm betting some of you have come up with some really nice solutions. If I didn't mind any length of battery cable (but I do, keep em short!) I'd go out to the wall, up and into a cable tray.

If I didn't mind fishing them and not being able to see them, I'd put conduit down in the bottom of the bilge.

There has to be something elegant at and around the engine and the bilge that works. Once I get to the walls, I'm good....

Thoughts/ideas/pics, what works on your boat?

My battery cables run along side the engine on top of a stringer (rail, can't recall the word) and the PO built a "box" around them complete with nails (ugh) to protect them.

Some others appear to be screwed direct to fiberglass with twist tie like holders. Doesn't that compromise the inner hull moisture-wise?

Others are just lying around. More ugh.

I'm betting some of you have come up with some really nice solutions. If I didn't mind any length of battery cable (but I do, keep em short!) I'd go out to the wall, up and into a cable tray.

If I didn't mind fishing them and not being able to see them, I'd put conduit down in the bottom of the bilge.

There has to be something elegant at and around the engine and the bilge that works. Once I get to the walls, I'm good....

Thoughts/ideas/pics, what works on your boat?

world !

world !