sbman

Guru

- Joined

- Jul 25, 2017

- Messages

- 828

- Location

- USA

- Vessel Name

- Second Chance

- Vessel Make

- 42' Uniflite Double Cabin

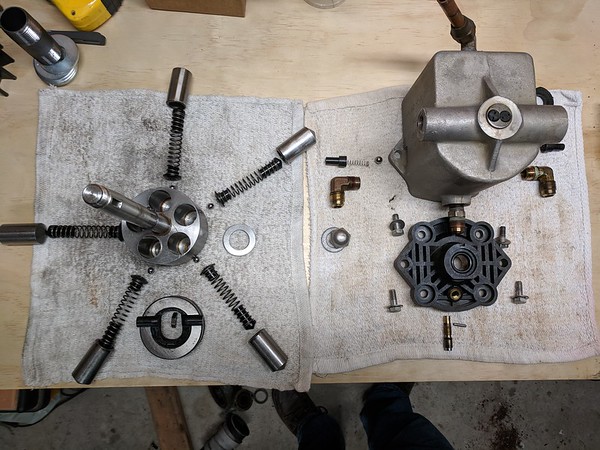

Both helm pumps on my Uniflite were weeping hydraulic fluid when I purchased it. After researching, the Teleflex Capilano 250V was discontinued in 1987 and Teleflex was aquired by SeaStar at some point. The new helm station was introduced as the 1250V in that time frame.

I emailed Seastar and asked about parts for the pumps. I was told there is a seal kit for the 1250V that would have the proper seals to reseal the pump, so I ordered it up. The kit includes a number of o-rings, a paper gasket and a plastic faceplate for the front shaft seal. To sum up the product, the kit didn't fit. Details to follow.

The 250V in it's native environment:

The seal kit provided by Sea Star

The 250V does not have a shuttle valve in it. This is a separate unit on the older systems that is in a unit called a 'Uniflow' valve which is located near the steering ram. It does not have a removable back portion as shown in the diagram for the 1250V, and also does not have the same type of check ball valves on the outputs.

I emailed Seastar and asked about parts for the pumps. I was told there is a seal kit for the 1250V that would have the proper seals to reseal the pump, so I ordered it up. The kit includes a number of o-rings, a paper gasket and a plastic faceplate for the front shaft seal. To sum up the product, the kit didn't fit. Details to follow.

The 250V in it's native environment:

The seal kit provided by Sea Star

The 250V does not have a shuttle valve in it. This is a separate unit on the older systems that is in a unit called a 'Uniflow' valve which is located near the steering ram. It does not have a removable back portion as shown in the diagram for the 1250V, and also does not have the same type of check ball valves on the outputs.