ORIF

Senior Member

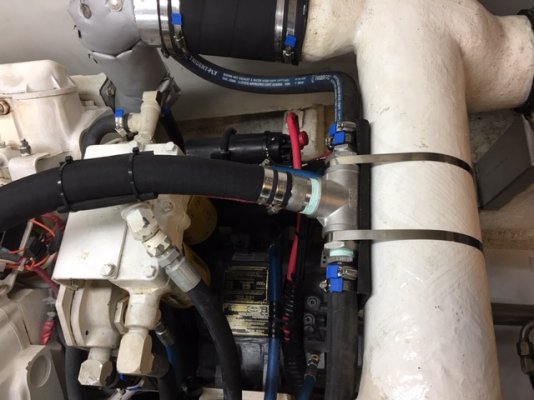

I’ve got twin 3208NAs in an ‘86 44’ Tollycraft.

I have about 3000 hours on the engines.

Short cruises a few times a year at the moment.

When I bought the boat 4 years ago, I replaced all 4 risers and all hoses. Standard Cat cast gold (I mean iron).

Any recommendations on care of these risers to slow down the need for eventual replacement?

Any thoughts on what their typical lifespan is?

Thanks,

Edward

I have about 3000 hours on the engines.

Short cruises a few times a year at the moment.

When I bought the boat 4 years ago, I replaced all 4 risers and all hoses. Standard Cat cast gold (I mean iron).

Any recommendations on care of these risers to slow down the need for eventual replacement?

Any thoughts on what their typical lifespan is?

Thanks,

Edward