I have the same motors on our Mainship 400, so I'll chime in on what I know, though I am far from an expert and you will likely get better advice from others on here.

Pic 1, strainer. No worries there, I have the same strainers, probably just a bad seal under the cap or dried salt from spills when checking the basket. Clean it up and keep an eye on it.

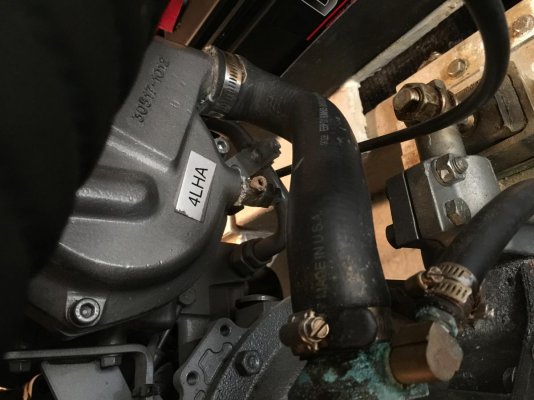

Pic 2, Wiring harness under the heat exchanger. This is a common spot to get wet as well, maybe the HE needs a new gasket or leaked at one time. This spot generally gets wet if you pull the cap off of the HE. PO should have cleaned the harness with fresh water after the service and sprayed it with some sort of corrosion spray, but if the connections there are OK, it's not a deal breaker.

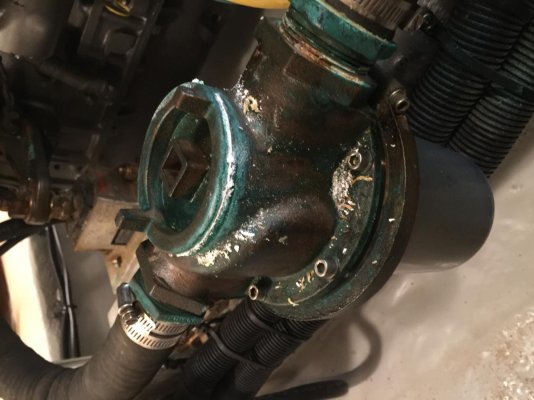

Pics 3 and 4, transmission oil cooler. I'd replace that. $500 to $1,000 depending on who does it is my guess.

Pic 5, Oil cooler (?) not sure on this one.

Pic 6, shaft seal, Is the hose clamp tight? It looks like it is or was leaking. Or maybe the seal is going bad and the water drips down onto it?

I had a lot of this sort of thing on my motors when I bought the boat 6 years ago. The mechanic who did our survey said that it MIGHT be and indication of an overheat at one time but he wasn't sure. Most of the spots you took pics of are areas that I cleaned up on my motors as well. I keep an eye on them, but haven't had any more issues. Maybe the hoses all need to be replaced with new clamps?