Riverguy- I generally agree with what you posted, but there is one important detail that you left out: Air exchange through the vent system.

True that thermal inertia (ballast in your terms) of a half load of fuel will cause fuel to often be below the dewpoint of the outside air, depending on what the cold/warm fronts are doing. Those fronts can have quite wide swings of temp and humidity here in the southeast.

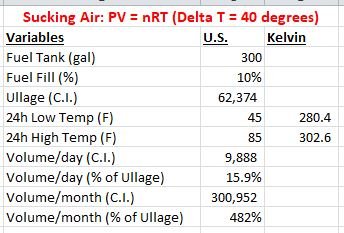

But there is not any significant flow of air in and out of the vent. Usually several feet of 5/8" ID hose. Yep due to thermal changes and barometric changes there will be some flow in and out of the vent. But do the math and the volume through those mechanisms is very small as a percentage of trapped air volume above the fuel level.

If there is not significant air flow through the tank from the outside air, the moisture content of the air above fuel simply will not change much.

Ski, you beat me to it, in order to generate significant condensation the movement of water-laden air into the tank has to occur.

To clarify, my test was done on vessels that were hauled out, tanks were partially full, so a generous air space, access ports were only removed for the inspection and then replaced.

One possible reason PS has written so much about this...because the myth is so pervasive.

Having said all that, regardless of the source of the water, it may not matter, what's important is it does occur to greater or lesser degrees from vessel to vessel, and therefore there should be a means of removing it. Ideally it's a sump and drain, or stripper tube. In other cases it's the primary fuel filter, however, in that case some water will remain as the fuel pick up is not close enough to the bottom of the tank to remove it all.

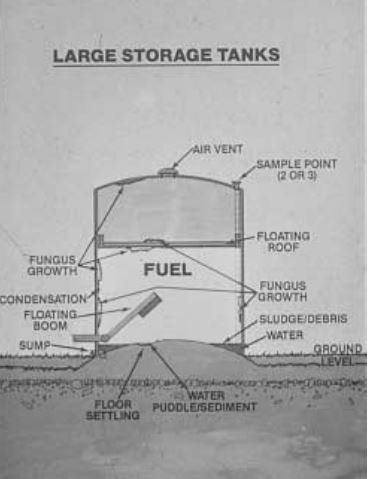

Water left in metallic tanks will cause corrosion, and water will support biological life in any tank (a byproduct of bacteria colonies in tanks is hydrogen sulfide, which is corrosive, as well as the skeletons of the single cell organisms when they die). Biocides address one of these issues, but not the other and I believe they provide a false sense of security.

I've replaced aluminum tanks that were just a few years old as a result of water entry, bio-fouling and corrosion, the tank bottoms looked like the proverbial Swiss cheese. See page 6 in this article

https://stevedmarineconsulting.com/wp-content/uploads/2014/03/Diesel_Primer115_04.pdf for details on contamination. Attached are a photos of the insides of a bio-fouled tank and the bottom of the tank whose bottom corroded as a result of water entry/contamination.

This article shows the inside of some contaminated tanks and filters

https://stevedmarineconsulting.com/cleaning-diesel-tanks/

In the case of the young tanks that were replaced, the water source turned out to be a hull mounted tank vent that intersected with the vessel's bow wave at just the planing transition speed, every time it passed through that transition, a slug of water would be pushed

uphill and into the tank.