Vashon_Trawler

Guru

- Joined

- Jun 13, 2013

- Messages

- 598

- Location

- USA

- Vessel Name

- M/V Sherpa

- Vessel Make

- 24' Vashon Diesel Cruiser

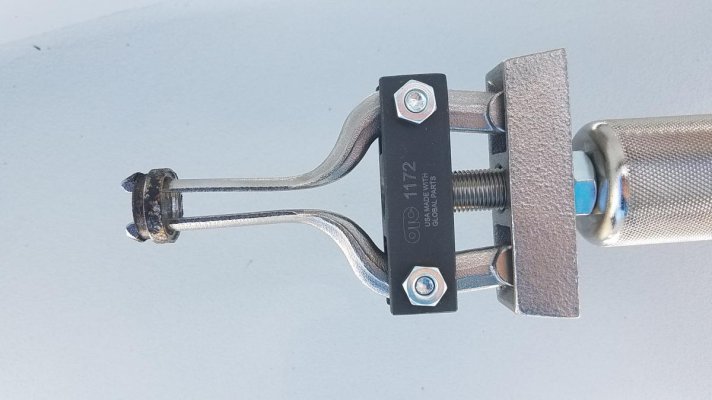

I was able to remove two out of three injector injector reducers for my MD2030, but the last one is not budging. I am concerned about damaging the injector threads or having metal shavings fall into the block. So far I have tried reverse pliers, which removed the other two; but the last one refuses to budge!

Is there a tool I should be using?

Thank you!

Is there a tool I should be using?

Thank you!

Attachments

Last edited: