Aft Deck Capt

Senior Member

- Joined

- May 18, 2014

- Messages

- 191

- Location

- US

- Vessel Name

- Long Shot

- Vessel Make

- 1978 Californian 42' LRC

Greetings all.

I've just completed a complete cooling system service that included pulling and de-scaling the exhaust elbows. They weren't as bad as some of the pics shared by other members but were moderately restricted at the spray head. Now the question is how long before they fail?

To buy some time, I drilled/tapped the brass plugs and zincs at the bottom of each elbow and installed petcock drains to eliminate the standing water column at shut down. An added nuisance but cheap insurance.

The plan was to run this season like this and replace them next winter abruptly changed when I dropped and cracked one Saturday loading up to go to the boat. I lightly ground out the hairline fracture and patched it with some S10 sealant. Yesterday I bolted them on and leak tested both engines -success! Shut down, drained each elbow and verified no internal or external raw water leaks on the dropped elbow.

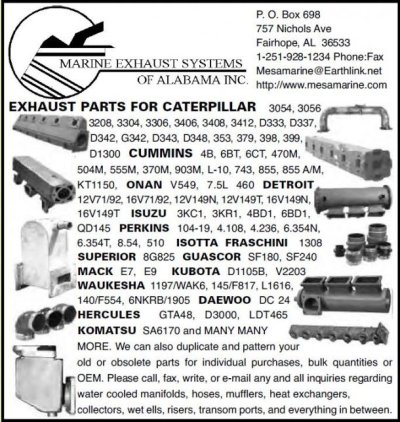

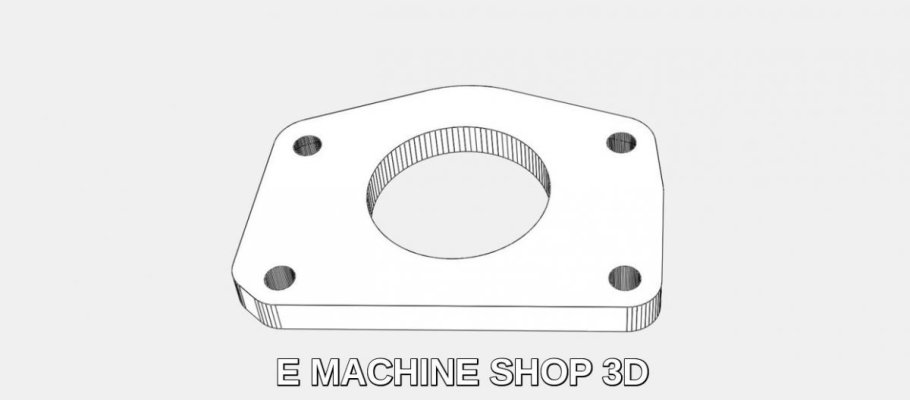

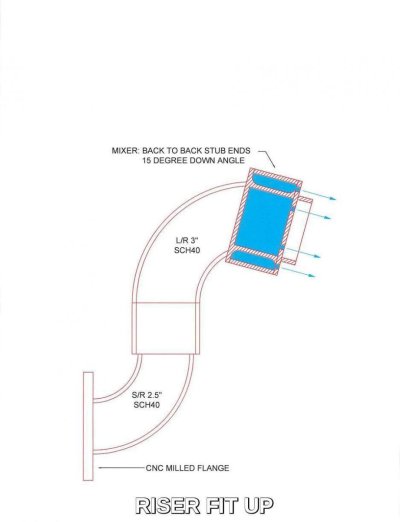

The thought of shelling out around $4500 for new Cat elbows kind of makes my speedo bunch up a bit! I'm considering fabricating new elbows out of some off the shelf sch40 316 fittings. Estimated cost is around $1500. Thoughts?

I've just completed a complete cooling system service that included pulling and de-scaling the exhaust elbows. They weren't as bad as some of the pics shared by other members but were moderately restricted at the spray head. Now the question is how long before they fail?

To buy some time, I drilled/tapped the brass plugs and zincs at the bottom of each elbow and installed petcock drains to eliminate the standing water column at shut down. An added nuisance but cheap insurance.

The plan was to run this season like this and replace them next winter abruptly changed when I dropped and cracked one Saturday loading up to go to the boat. I lightly ground out the hairline fracture and patched it with some S10 sealant. Yesterday I bolted them on and leak tested both engines -success! Shut down, drained each elbow and verified no internal or external raw water leaks on the dropped elbow.

The thought of shelling out around $4500 for new Cat elbows kind of makes my speedo bunch up a bit! I'm considering fabricating new elbows out of some off the shelf sch40 316 fittings. Estimated cost is around $1500. Thoughts?