trawlerdrake

Member

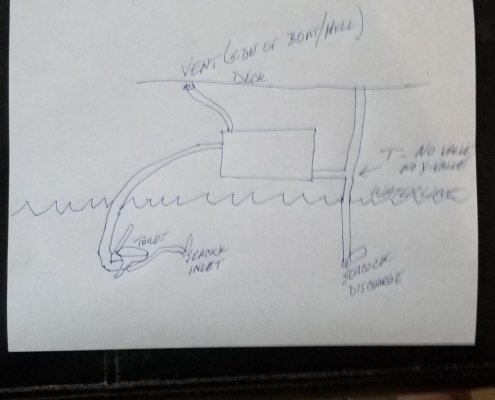

Just looking at a boat with head set up attached Is this OK ?

Notice:

There is no vented loop -- there is a vent that goes from the top of the tank to the side of the hull.

There is no Y valve -- but I can close the seacock and prevent discharge. It would be possible to add a way to lock that shut (although currently it is not locked).

I don't think it would siphon because of the vent to the top -- but this is my main concern.

I am guessing that if I locked the thru hull down the coast guard would be ok

Other thing would be will be laying down in the pipe between the tank and the thru hull ? would a pump out still suck it all out?

any advice appreciated thanks

Notice:

There is no vented loop -- there is a vent that goes from the top of the tank to the side of the hull.

There is no Y valve -- but I can close the seacock and prevent discharge. It would be possible to add a way to lock that shut (although currently it is not locked).

I don't think it would siphon because of the vent to the top -- but this is my main concern.

I am guessing that if I locked the thru hull down the coast guard would be ok

Other thing would be will be laying down in the pipe between the tank and the thru hull ? would a pump out still suck it all out?

any advice appreciated thanks