You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone opened an inspection cover for a fuel tank?

- Thread starter Steve91T

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

O C Diver

Guru

- Joined

- Dec 16, 2010

- Messages

- 12,868

- Location

- USA

- Vessel Name

- Slow Hand

- Vessel Make

- Cherubini Independence 45

Be wary of this boat! You are in for a rough time if the tanks are in bad shape. From personal experience I can tell you that if there is enough crud in the tanks the Racors WILL fail and pass the crud to the block mounted filters. Even with fresh filter elements. Once the crud is in the block mounted filters they too will fail and gunk up the works. The engines are now running very poorly and awaiting service. A shame, very low hours John Deeres.

The stuff in the 5 gal white bucket is what came out of the block mounted primary filter when I dumped it into the bucket, that's crud and water mixed. The stuff in the plastic water bottle is the first draining of the Racor bowl. The Racor bowl is self explanatory. I no longer trust Racors.

For those who are curious this wasn't my boat, it was a delivery. About 18 hrs from the dock we slowed for heavy weather. At about 33 hrs from the dock the John Deere 4045T engine panels reported water in the fuel. There were no vacuum gauges installed on the Racors to indicate their status. 2.5 hrs of struggling with Racors and block mounted filters later we limped into port at low speed. We cleaned everything as well as we could, sea trials, lots of spare filters and off we went again. For the remainder of the delivery in sloppy weather the Racors were drained every hour, every 3 hrs in good weather. The block mounted primaries were drained twice a day. The block mounted primaries showed no more crud but did show small amounts of water.

The owner had an offer on the boat but is now facing considerable expense getting it ready for sale. The tanks are original 1981 steel tanks. The seller has decided to accept a lower offer in lieu of opening and cleaning the tanks. I wish the buyer luck.

I think the point that may be missed here is that the racors are very good seperator filters, but there is a limit to what any filter system will handle. Poor 5 to 10 gallons of water in most any of our fuel tanks, and it will pass through all the filters and shut the engine down.

Not to be to critical of you, but any old boat that I'm running for the first time, I will be checking the Racors regularly for contaminated fuel. When you get into heavy weather, you have to know everything in the bottom of the fuel tanks will be getting stirred up. If you're not going to stop, hourly Racor checks would be a priority.

Ted

dhays

Guru

- Joined

- May 26, 2015

- Messages

- 9,045

- Location

- United States

- Vessel Name

- Kinship

- Vessel Make

- North Pacific 43

Putting money into a boat that you're not 100 percent on is a serious risk. Kind of makes it hard to walk away if something else is a no-go. Personally I would not do it.

^^^ this.

dhays

Guru

- Joined

- May 26, 2015

- Messages

- 9,045

- Location

- United States

- Vessel Name

- Kinship

- Vessel Make

- North Pacific 43

I believe that the boat the OP is looking at has a dual Racor system? I could have gotten lost in the thread though.

In my own ignorant opinion, a Dual Racor system is quite good as long as it is used properly. Sure the tanks should be cleaned and the fuel should be externally filtered before being used (or given away and fresh fuel be used after the tanks are cleaned). I would still expect some crud to get kicked up at first.

Running a dual Racor on one filter and having a vacuum gauge installed means you should be able to avoid any problems. However, the operator has to use it properly. I’d be checking the bowl on the active filter hourly at first looking for water and vacuum rise. If so, switch to the other filter and drain and change the first. Keep doing this until the problems don’t recur. A case of filters will do wonders for staying out of trouble.

In my own ignorant opinion, a Dual Racor system is quite good as long as it is used properly. Sure the tanks should be cleaned and the fuel should be externally filtered before being used (or given away and fresh fuel be used after the tanks are cleaned). I would still expect some crud to get kicked up at first.

Running a dual Racor on one filter and having a vacuum gauge installed means you should be able to avoid any problems. However, the operator has to use it properly. I’d be checking the bowl on the active filter hourly at first looking for water and vacuum rise. If so, switch to the other filter and drain and change the first. Keep doing this until the problems don’t recur. A case of filters will do wonders for staying out of trouble.

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,287

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

Not all old boats have bad fuel tanks. My boat has the original 1987 tanks. The boat had been sitting for a couple of years. We changed the primaries and the secondaries before we started home 1400 miles. That was 2 years ago. Crossing Lake Ontario we had 5 to 6 footers on our quarter. Rocked and rolled for hours. I am about to change the filters this week for the first time since I don’t want to go more than 2 years. My tanks show no rust where I can see them. I am thinking about proactively replacing them so that I can do it on my schedule. I think I may pull one engine up out of the engine room and replace the tank on that side while cleaning up the engine room at the same time. Then do the other tank the next winter.

Portage_Bay

Guru

- Joined

- Oct 19, 2015

- Messages

- 2,453

- Location

- United States

- Vessel Name

- Pacific Myst

- Vessel Make

- West Bay 4500

I think the point that may be missed here is that the racors are very good seperator filters, but there is a limit to what any filter system will handle. Poor 5 to 10 gallons of water in most any of our fuel tanks, and it will pass through all the filters and shut the engine down.

Not to be to critical of you, but any old boat that I'm running for the first time, I will be checking the Racors regularly for contaminated fuel. When you get into heavy weather, you have to know everything in the bottom of the fuel tanks will be getting stirred up. If you're not going to stop, hourly Racor checks would be a priority.

Ted

In my nearly 5 decades on the water as both a professional and recreational boater I have never felt that Racors are the best. What they are is the most common, meaning filter elements and parts are easily available nearly everywhere in North America.

For an expert's opinion on effective fuel filtration read this often posted link. Marine Fuel Filtration “The Seaboard Way”

South of Heaven

Guru

- Joined

- May 11, 2017

- Messages

- 1,167

- Location

- USA

- Vessel Name

- Slow Lane

- Vessel Make

- 2005 Silverton 35 Motoryacht

Portage Bay: Thanks for the link. Good read.

Deckape

Senior Member

Filtering fuel will help see if you have dirty fuel. Tank cleaning is another animal. Using high pressure fuel to remove the scabs of gunk on the tank may open up areas that maybe thin,rusty , and the hard scab is the only thing keeping the fuel from leaking.

That was my problem. Looking at the tank after cutting it to remove you could see that the hard caked on sediment had attached itself to the tank. Im just saying ,be careful with tank cleaning may cause future leaks, fuel polishing not so much... Just my $ .02

That was my problem. Looking at the tank after cutting it to remove you could see that the hard caked on sediment had attached itself to the tank. Im just saying ,be careful with tank cleaning may cause future leaks, fuel polishing not so much... Just my $ .02

JDCAVE

Guru

- Joined

- Apr 3, 2011

- Messages

- 2,907

- Location

- Canada

- Vessel Name

- Phoenix Hunter

- Vessel Make

- Kadey Krogen 42 (1985)

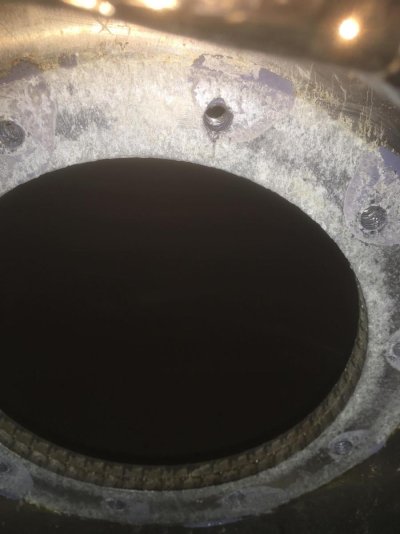

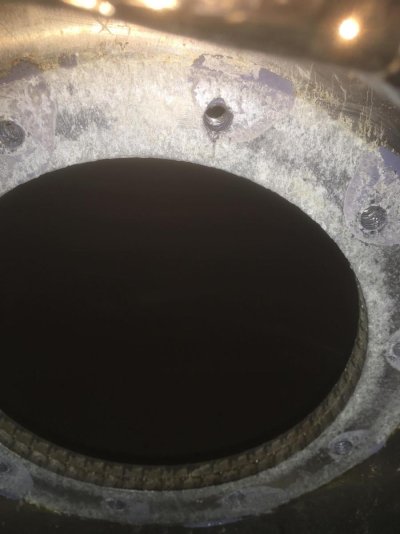

I just opened one of my fuel tank ports to determine status. The PO installed new tanks in 2010 and I wanted to see what had changed and if there was any accumulation of asphaltenes. It was fine and I shut it up and was done.

If the tanks are properly cleaned I think you will be good to go. But you’re still hoping that there is no accumulation in the lines.

BTW, this is an expensive process. I was quoted $3,300 Cdn for my 4 tanks for the same process using a pressurized fuel jet. They expected it to be a 12 hour job. Opening the tank revealed it was fine and I didn’t have to do anymore. Mind you I completely emptied the tank and opened the port nearest the fuel pickup tubes.

If the tanks are properly cleaned I think you will be good to go. But you’re still hoping that there is no accumulation in the lines.

BTW, this is an expensive process. I was quoted $3,300 Cdn for my 4 tanks for the same process using a pressurized fuel jet. They expected it to be a 12 hour job. Opening the tank revealed it was fine and I didn’t have to do anymore. Mind you I completely emptied the tank and opened the port nearest the fuel pickup tubes.

IRENE

Guru

JDCAVE,

Thanks for that.

How long did the job take? I need to do the same on IRENE - once the fuel is burned off a bit towards fall.

Did you need to replace the gasket under the cover you removed?

Thanks for that.

How long did the job take? I need to do the same on IRENE - once the fuel is burned off a bit towards fall.

Did you need to replace the gasket under the cover you removed?

Last edited:

JDCAVE

Guru

- Joined

- Apr 3, 2011

- Messages

- 2,907

- Location

- Canada

- Vessel Name

- Phoenix Hunter

- Vessel Make

- Kadey Krogen 42 (1985)

JDCAVE,

Thanks for that.

How long did the job take? I need to do the same on IRENE - once the fuel is burned off a bit towards fall.

Did you need to replace the gasket under the cover you removed?

I detail this a bit more here:

http://www.trawlerforum.com/forums/s6/cleaning-fuel-tanks-34481.html

It didn't take long. I used a 1/2" long socket. The bolts were tight but not excessively so. Most of the time was spent cleaning up the excessive amount of pipe joint compound the PO had used as well as the aluminum port plate. BTW, it seems this PJC seemed to cause some "oxidation" of the aluminum, even some small amount of poultice corrosion. I reused the gasket after cleaning it up. In one of his articles, Steve D'Antonio indicated the use of silicone "grease" was appropriate on the gasket, so I used that.

I mention in the thread above that I intend to move the ESI fuel polish system to the inverter side of the AC panel so I can use it while underway. I contend that you need "agitation" or "movement" of the fuel in the tanks to free up the asphaltens for filtering by the system. Running it whilst still at the dock is not that effective. The PO installed it so I may as well use it. right now it's mostly use to rebalance the fuel in the tanks to improve trim of the boat.

Jim

O C Diver

Guru

- Joined

- Dec 16, 2010

- Messages

- 12,868

- Location

- USA

- Vessel Name

- Slow Hand

- Vessel Make

- Cherubini Independence 45

In my nearly 5 decades on the water as both a professional and recreational boater I have never felt that Racors are the best. What they are is the most common, meaning filter elements and parts are easily available nearly everywhere in North America.

For an expert's opinion on effective fuel filtration read this often posted link. Marine Fuel Filtration “The Seaboard Way”

Being an expert on somethings, doesn't make you an expert on everything.

Parker Hannifin, the parent company or Racor is an expert of fuel, air, and may other forms of filtration. Equipment manufacturers go to them to solve problems and manufacture solutions. Don't think you will find Tony at that level.

I have read Tony's article on fuel fitration before. IMO, not having a bowl in the bottom of your first separator is like giving up engine gauges at the helm for idiot lights. Without the bowl, you have to wait for fuel problems to reach critical mass. With the bowl, engine checks allow you to see fuel problems developing before they reach critical mass.

Ted

Did they just paint the engines? What a difference from your fist post in this thread. They look great now.

I was thinking the same thing. I’m not sure, but I’m going to find out.

Check the header tank pressure caps. I’d replace them if they were just painted over from the looks of the first photo. What did your surveyor say?

dhays

Guru

- Joined

- May 26, 2015

- Messages

- 9,045

- Location

- United States

- Vessel Name

- Kinship

- Vessel Make

- North Pacific 43

I certainly don’t think that Racors are the “best” filters out there. My point a few posts above was that with a dual Racors as your primary filtration you have all the tools you need to be able to ensure that your engine gets clean fuel. The problem is that the operator actually has to use them correctly. That means checking them.

I don’t check mine that often, usually about every 2-3 days of using the boat. However, I’ve never had any debri or water in the Racors. Last summer I completely disassembled and cleaned them out when I added a stop-cock to the bottom of each. After 7 years of use, about 1000 engine hours, I only got a very slight film off the inside of the filter housing when wiped down with a shop towel. The point is that I’ve got very clean fuel. For Steve, I would expect the fuel to have some crud in it, even after the tanks are cleaned and new fuel is added. Checking and changing filters as needed would be something I would anticipate and a dual Racor system is convenient for that.

I have read Tony’s article a few times over the past 3 years. I think in many ways it makes a lot of sense. Keep in mind that he recommends draining a fuel sample from the bottom of the separator before running the engine. When done, this is better than trying to visually inspect a Racor. One of the reasons I put stop-cocks on my Racors. Easy to drain some fuel and see if there is any water there that would be missed trying to see in the bowl with the metal flame shield around it.

Since I have clean fuel and the boat came with a dual Racor system, there is no reason for me to need to change. However, if I was consistently getting fuel contamination or had questionable tanks, then I might consider adding a bulk filter/separator before the Racors. OTOH, I likely would just check the Racors more frequently and change the filters more often. They are certainly easy to change.

I don’t check mine that often, usually about every 2-3 days of using the boat. However, I’ve never had any debri or water in the Racors. Last summer I completely disassembled and cleaned them out when I added a stop-cock to the bottom of each. After 7 years of use, about 1000 engine hours, I only got a very slight film off the inside of the filter housing when wiped down with a shop towel. The point is that I’ve got very clean fuel. For Steve, I would expect the fuel to have some crud in it, even after the tanks are cleaned and new fuel is added. Checking and changing filters as needed would be something I would anticipate and a dual Racor system is convenient for that.

I have read Tony’s article a few times over the past 3 years. I think in many ways it makes a lot of sense. Keep in mind that he recommends draining a fuel sample from the bottom of the separator before running the engine. When done, this is better than trying to visually inspect a Racor. One of the reasons I put stop-cocks on my Racors. Easy to drain some fuel and see if there is any water there that would be missed trying to see in the bowl with the metal flame shield around it.

Since I have clean fuel and the boat came with a dual Racor system, there is no reason for me to need to change. However, if I was consistently getting fuel contamination or had questionable tanks, then I might consider adding a bulk filter/separator before the Racors. OTOH, I likely would just check the Racors more frequently and change the filters more often. They are certainly easy to change.

Sailor of Fortune

Guru

In my nearly 5 decades on the water as both a professional and recreational boater I have never felt that Racors are the best. What they are is the most common, meaning filter elements and parts are easily available nearly everywhere in North America.

For an expert's opinion on effective fuel filtration read this often posted link. Marine Fuel Filtration “The Seaboard Way”

Agreed!

Portage_Bay

Guru

- Joined

- Oct 19, 2015

- Messages

- 2,453

- Location

- United States

- Vessel Name

- Pacific Myst

- Vessel Make

- West Bay 4500

..... I’ve got some reading to do. I have no idea what a a Racor is

Racor is a fuel filter system by Parker Hannifin. The most popular is the Turbine Series.

As you can see not all agree Racor is the best. But all of us agree if the filter / separator, no matter the manufacturer, is not properly used and maintained it will fail.

Clean your tanks, keep 'em clean, maintain your filter / separator or face the consequences.

JimW

Senior Member

- Joined

- Apr 12, 2017

- Messages

- 160

- Location

- United States

- Vessel Name

- CLASSEA

- Vessel Make

- 1988 Defever 41

JDCAVE

Guru

- Joined

- Apr 3, 2011

- Messages

- 2,907

- Location

- Canada

- Vessel Name

- Phoenix Hunter

- Vessel Make

- Kadey Krogen 42 (1985)

The problem with the Racor system is the ABYC recommendation for the heat shield. It makes it pretty much impossible to see if you have water in it. The PO put petcocks on them but he gummed them up with pipe joint compound. I drain them when I replace the filters by siphoning out the fuel and tossing it in the disposal tank.

dhays

Guru

- Joined

- May 26, 2015

- Messages

- 9,045

- Location

- United States

- Vessel Name

- Kinship

- Vessel Make

- North Pacific 43

The problem with the Racor system is the ABYC recommendation for the heat shield. It makes it pretty much impossible to see if you have water in it. The PO put petcocks on them but he gummed them up with pipe joint compound. I drain them when I replace the filters by siphoning out the fuel and tossing it in the disposal tank.

Replacing the petcocks isn’t too difficult. Maybe replace each as you change the filters. I know what you mean about the heat shield. I considered removing them when I disassembled and cleaned the housings, but chickened out.

psneeld

Guru

Like most TF discussions...... best...... is an elusive term.

Many feel that their boat should not only exceed USCG standards, but up to date ABYC standards.....and just to be safe, NASA standards.

Just like the doctor that graduated at the bottom of his class....he is still a doctor and if you need one.....he just might do fine...as not every situation requires the best.

How many sea miles have been traversed with Racor turbine filters? Just about every commercial boat I have run had them. So yeah....more common but not the best?.... does it matter if they do the job?

Many feel that their boat should not only exceed USCG standards, but up to date ABYC standards.....and just to be safe, NASA standards.

Just like the doctor that graduated at the bottom of his class....he is still a doctor and if you need one.....he just might do fine...as not every situation requires the best.

How many sea miles have been traversed with Racor turbine filters? Just about every commercial boat I have run had them. So yeah....more common but not the best?.... does it matter if they do the job?

Wxx3

Dauntless Award

- Joined

- Jan 10, 2013

- Messages

- 2,820

- Location

- USA

- Vessel Name

- Dauntless

- Vessel Make

- Kadey Krogen 42 - 148

I believe that the boat the OP is looking at has a dual Racor system? I could have gotten lost in the thread though.

In my own ignorant opinion, a Dual Racor system is quite good as long as it is used properly. Sure the tanks should be cleaned and the fuel should be externally filtered before being used (or given away and fresh fuel be used after the tanks are cleaned). I would still expect some crud to get kicked up at first.

Running a dual Racor on one filter and having a vacuum gauge installed means you should be able to avoid any problems. However, the operator has to use it properly. I’d be checking the bowl on the active filter hourly at first looking for water and vacuum rise. If so, switch to the other filter and drain and change the first. Keep doing this until the problems don’t recur. A case of filters will do wonders for staying out of trouble.

Very well said.

That's also been my experience.

It's no big deal to open inspection ports and clean up remaining crud.

I used cheap mops to wipe walls and shop vac to suck up whatever is left.

O C Diver

Guru

- Joined

- Dec 16, 2010

- Messages

- 12,868

- Location

- USA

- Vessel Name

- Slow Hand

- Vessel Make

- Cherubini Independence 45

The problem with the Racor system is the ABYC recommendation for the heat shield. It makes it pretty much impossible to see if you have water in it. The PO put petcocks on them but he gummed them up with pipe joint compound. I drain them when I replace the filters by siphoning out the fuel and tossing it in the disposal tank.

I have the heat shields on my dual Racor 1000. Find it quite easy to see the contents of the bowls with a bright LED flashlight aimed from behind toward the bottom of the bowl. In the USA fuel is dyed red, so there would be an even more pronounced difference between fuel and water.

Find a bright LED flashlight indispensable for engine room checks, especially underway.

Ted

boatruptcy

Senior Member

Visual inspection is somewhat overrated in my opinion concerning the Racor's and definitely not worth the trade off of the mess they create when changing, especially underway. If you have vacuum gauges with a drag needle and solid filters that have drains, it's a simple process to open and drain a few drops into a tupperware container and examine for water and crud. I removed my racor and replaced with filter heads and run solid spin on filters now with drains.

O C Diver

Guru

- Joined

- Dec 16, 2010

- Messages

- 12,868

- Location

- USA

- Vessel Name

- Slow Hand

- Vessel Make

- Cherubini Independence 45

No mess in changing the racor. Just drain the housing through the petcock in the bottom of the bowl before removing the element.Visual inspection is somewhat overrated in my opinion concerning the Racor's and definitely not worth the trade off of the mess they create when changing, especially underway. If you have vacuum gauges with a drag needle and solid filters that have drains, it's a simple process to open and drain a few drops into a tupperware container and examine for water and crud. I removed my racor and replaced with filter heads and run solid spin on filters now with drains.

If you did periodic checks of the separator bowl while underway, you wouldn't be trying to change a filter underway.

Drawing fuel samples while underway is unrealistic. While it probably isn't necessary running 8 hours or less, if you're doing overnight trips or multiple day runs up the coast, knowing fuel filtration status becomes more important.

Ted

Similar threads

Latest posts

-

Looking for convenient pump for dewatering bilges other than hand pump

- Latest: guy with a boat

-

-

-

-

-

-

-