The Other Gary

Senior Member

- Joined

- Sep 18, 2016

- Messages

- 336

- Location

- Canada

- Vessel Name

- Adios Dinero

- Vessel Make

- Bayliner 3988 2 x 330 Cummins

Everyone with non electronic engines should have some basic knowledge of their systems and workarounds for the eventuality of having to start a diesel to get home.

Mine are Cummins 6bta 330's and newly rebuilt by myself from new long blocks.

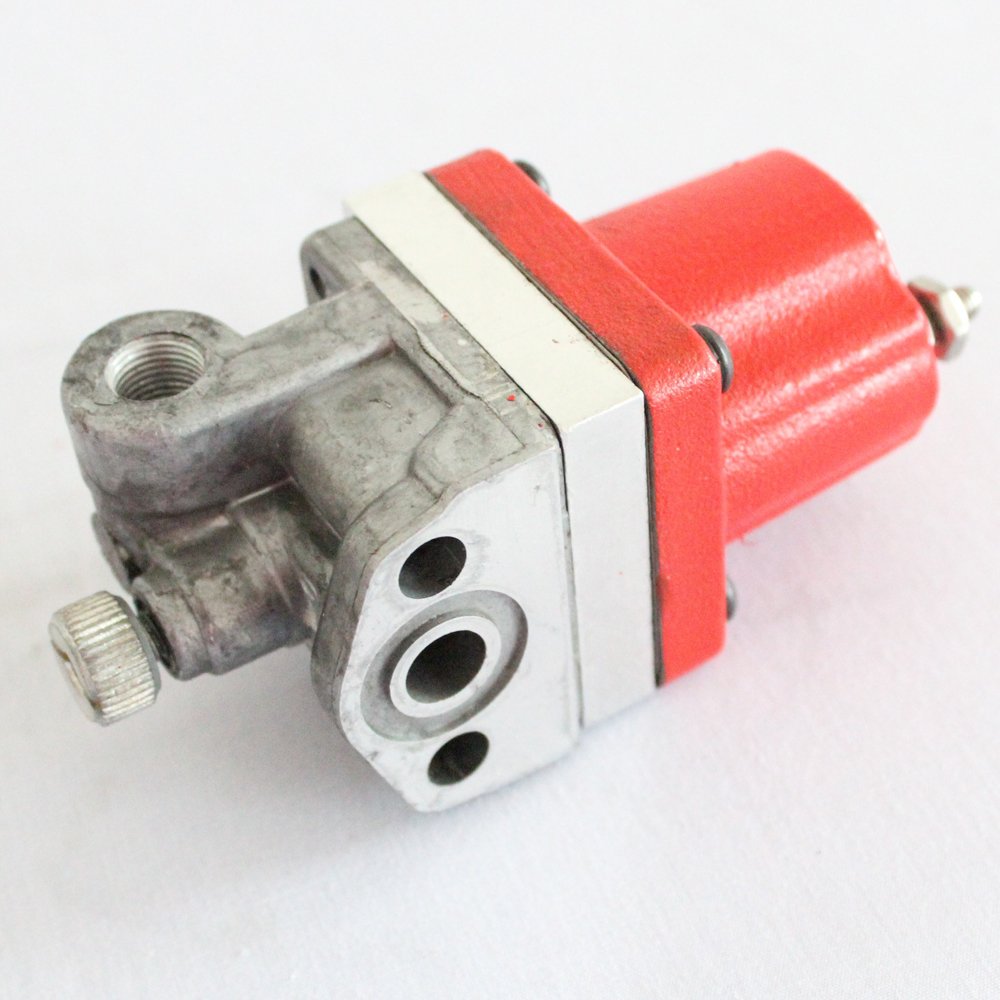

The same solenoid is used for the starter (1) and the air heaters (2) so having a spare(s) or knowing where to borrow one on the engine will help get you home Because jumping a bad solenoid will get you nowhere. Knowing how your fuel is turned off and on will help you know how to turn it on if you lose power and need to restart to get home.

Know where your engine mounted breaker is located and what it looks like. On a 6bta it is a red (or white if you didn't tape it over when painting) push button on the top rear port side near the lifting lugs.

If you have fuel, air and a method of spinning over the engine you should be able to get home.

I carry a spare starter as well.

It is important to know that Cummins starter bolts need a 10mm 12 point socket for their special bolt heads. It is the only place on the engine requiring a 12 point socket. I have a brand new one wire tied to the new starter just for this reason.

Mine are Cummins 6bta 330's and newly rebuilt by myself from new long blocks.

The same solenoid is used for the starter (1) and the air heaters (2) so having a spare(s) or knowing where to borrow one on the engine will help get you home Because jumping a bad solenoid will get you nowhere. Knowing how your fuel is turned off and on will help you know how to turn it on if you lose power and need to restart to get home.

Know where your engine mounted breaker is located and what it looks like. On a 6bta it is a red (or white if you didn't tape it over when painting) push button on the top rear port side near the lifting lugs.

If you have fuel, air and a method of spinning over the engine you should be able to get home.

I carry a spare starter as well.

It is important to know that Cummins starter bolts need a 10mm 12 point socket for their special bolt heads. It is the only place on the engine requiring a 12 point socket. I have a brand new one wire tied to the new starter just for this reason.

Last edited:

All of this information will be employed, Starting tomorrow. Thanks each of you proving once again the worth of the forum.

All of this information will be employed, Starting tomorrow. Thanks each of you proving once again the worth of the forum.